Cov khoom

-

YY-L2B Zipper Load Pull Tester

Siv rau kev sim lub neej ntawm cov hlau, kev txhaj tshuaj molding thiab nylon zipper nyob rau hauv cov ntaub ntawv load thiab rub lub sij hawm

-

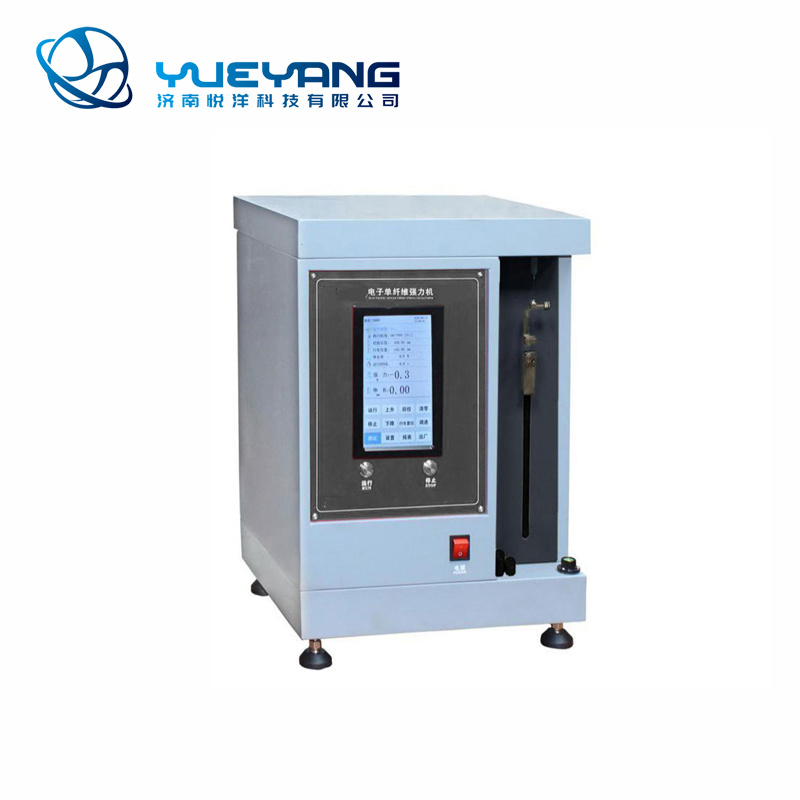

YY001Q Tib Fiber Zog Tester (Pneumatic Fixture)

Siv rau kev ntsuam xyuas lub zog tawg, elongation ntawm kev tawg, thauj khoom ntawm elongation ruaj khov, elongation ntawm cov khoom ruaj khov, nkag thiab lwm yam khoom ntawm ib leeg fiber ntau, hlau hlau, plaub hau, carbon fiber, thiab lwm yam.

-

YY213 Textiles Instant Contact Txias Tester

Siv los ntsuas qhov txias ntawm pajamas, txaj, ntaub thiab ris tsho hauv qab, thiab tuaj yeem ntsuas qhov thermal conductivity.

-

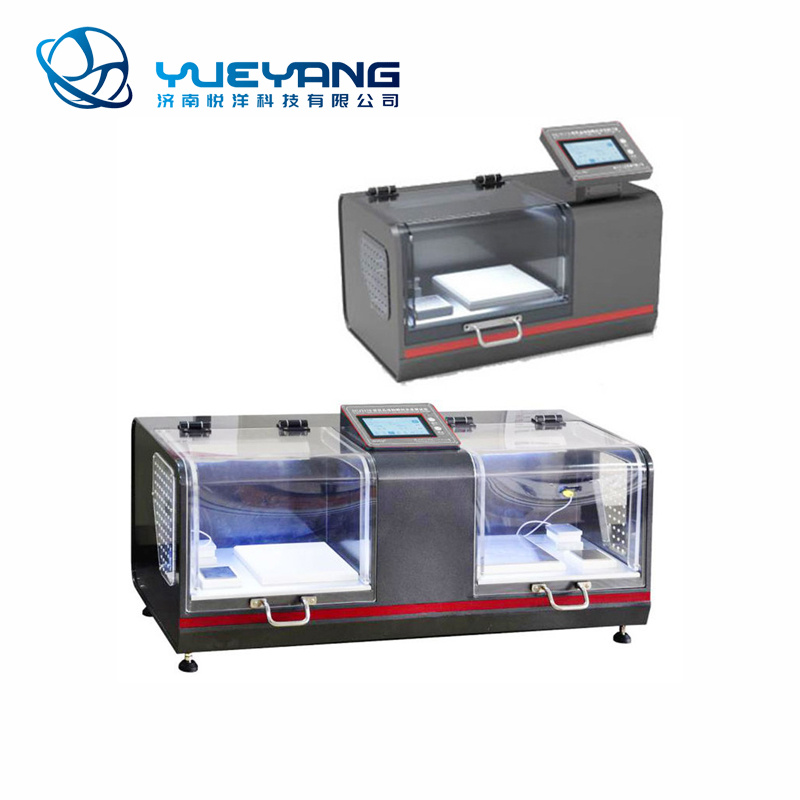

YY-SW-12AC-Color ceev ceev rau ntxuav tester

[Scope ntawm daim ntawv thov]

Nws yog siv rau kev ntsuam xyuas cov xim ceev rau kev ntxuav, qhuav tu thiab shrinkage ntawm ntau yam textiles, thiab kuj rau kev ntsuam xyuas cov xim ceev rau ntxuav ntawm dyes.

[Hais txog Standards]

AATCC61/1 A / 2 A / 3 A / 4 A / 5 A, JIS L0860/0844, BS1006, GB/T3921 1/2/3/4/5, ISO105C01/02/03/04/05/06/08 , lwm

[Technical parameters]

1. Test khob muaj peev xwm: 550ml (φ75mm × 120mm) (GB, ISO, JIS thiab lwm yam qauv)

1200ml (φ90mm × 200mm) (AATCC txuj)

6 PCS (AATCC) lossis 12 PCS (GB, ISO, JIS)

2. Kev ncua deb ntawm qhov chaw ntawm lub rotating ncej mus rau hauv qab ntawm lub khob xeem: 45mm

3. Kev sib hloov ceev

40 ± 2) r / min

40 ± 2) r / min4. Lub sij hawm tswj ntau yam

0 ~ 9999) feeb

0 ~ 9999) feeb5. Lub sij hawm tswj qhov yuam kev: ≤ ± 5s

6. Kev tswj qhov kub thiab txias: chav tsev kub ~ 99.9 ℃;

7. Kev tswj qhov kub thiab txias: ≤ ± 2 ℃

8. Cov txheej txheem cua sov: hluav taws xob cua sov

9. Fais fab mov: AC380V ± 10% 50Hz 8kW

10. Tag nrho qhov loj

930 × 690 × 840) hli

930 × 690 × 840) hli11. Nyhav: 165kg

Txuas ntxiv: 12AC txais cov qauv ntawm studio + chav preheating.

-

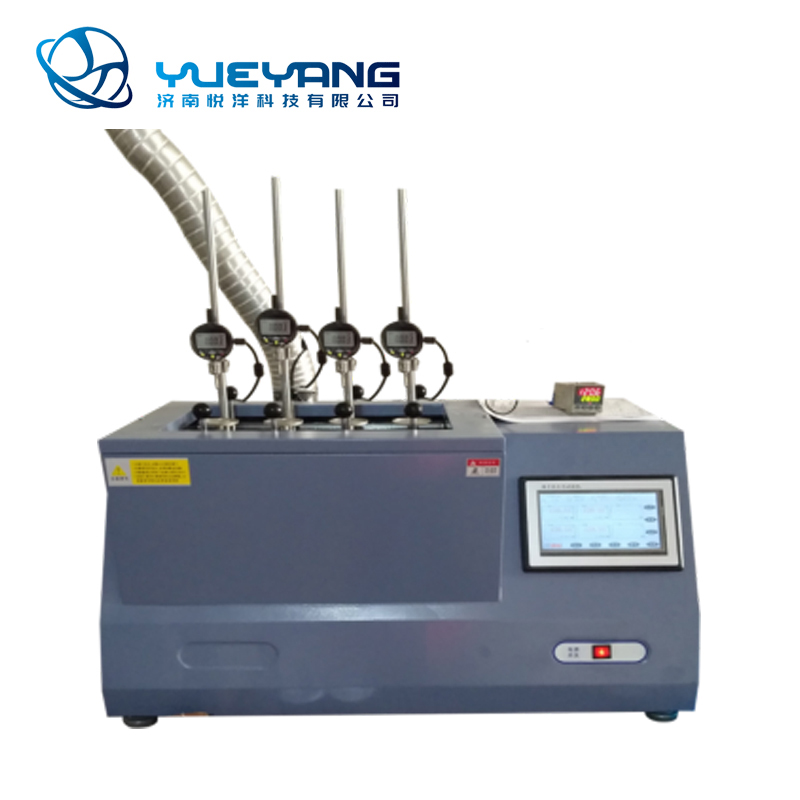

YYP-HDT VICAT Tester

HDT VICAT TESTER yog siv los txiav txim siab cua sov deflection thiab Vicat softening kub ntawm cov yas, roj hmab thiab lwm yam thermoplastic, Nws yog dav siv nyob rau hauv kev tsim, kev tshawb fawb thiab kev qhia ntawm yas raw cov ntaub ntawv thiab cov khoom. Cov cuab yeej siv tau zoo hauv cov qauv, zoo nkauj hauv cov duab, ruaj khov hauv qhov zoo, thiab muaj lub luag haujlwm ntawm cov pa paug paug thiab cua txias. Siv advanced MCU (multi-point micro-control unit) tswj qhov system, tsis siv neeg ntsuas thiab tswj qhov kub thiab txias thiab deformation, tsis siv neeg suav cov txiaj ntsig ntawm kev xeem, tuaj yeem rov ua dua los khaws 10 cov ntaub ntawv xeem. Cov cuab yeej no muaj ntau yam qauv xaiv los ntawm: tsis siv neeg LCD zaub, ntsuas tsis siv neeg; micro-control tuaj yeem txuas cov khoos phis tawj, tshuab luam ntawv, tswj los ntawm khoos phis tawj, kuaj software WINDOWS Suav (English) interface, nrog kev ntsuas tsis siv neeg, nkhaus ntawm lub sijhawm, cov ntaub ntawv khaws cia, luam ntawv thiab lwm yam haujlwm.

Technical parameter

1. Temperature tswj ntau yam: chav tsev kub txog 300 degrees centigrade.

2. Cua sov tus nqi: 120 C / h [(12 + 1) C / 6min]

50 C / h [(5 + 0.5) C / 6min]

3. Qhov kub siab tshaj plaws yuam kev: + 0.5 C

4. Kev ntsuas deformation ntau: 0 ~ 10mm

5. Qhov siab tshaj plaws deformation ntsuas qhov yuam kev: + 0.005mm

6. qhov tseeb ntawm kev ntsuas deformation yog: + 0.001mm

7. qauv khib (kuaj chaw nres tsheb): 3, 4, 6 (yeem)

8. txhawb nqa: 64mm, 100mm

9. qhov hnyav ntawm lub load lever thiab lub taub hau siab (kab koob): 71g

10. cua sov nruab nrab yuav tsum tau: methyl silicone roj los yog lwm yam xov xwm uas teev nyob rau hauv tus qauv (flash point siab tshaj 300 degrees Celsius)

11. cua txias hom: dej hauv qab 150 degrees Celsius, ntuj txias ntawm 150 C.

12. muaj qhov txwv qhov kub thiab txias, tsis siv neeg tswb.

13. hom zaub: LCD zaub, kov npo

14. Qhov ntsuas kub tuaj yeem tso tawm, qhov ntsuas kub siab tuaj yeem teeb tsa, ntsuas qhov ntsuas kub tuaj yeem raug kaw, thiab cov cua sov tuaj yeem nres tau tom qab qhov ntsuas kub nce mus txog qhov txwv.

15. deformation ntsuas txoj kev: tshwj xeeb high-precision digital dial gauge + tsis siv neeg tswb.

16. Nws muaj qhov tsis siv neeg tshem tawm cov pa luam yeeb, uas tuaj yeem cuam tshuam cov pa luam yeeb thiab tswj kom muaj huab cua zoo nyob hauv tsev txhua lub sijhawm.

17. Fais fab mov voltage: 220V + 10% 10A 50Hz

18. cua sov fais fab: 3kW

-

YY630 Salt Spray Corrosion Test Chamber

Lub tshuab no yog siv rau kev kho deg ntawm ntau yam ntaub ntawv, suav nrog txheej, electroplating, inorganic thiab organic daim tawv nqaij zaj duab xis, cathodic kev kho mob ntawm anti-xeb roj thiab lwm yam kev kho corrosion, sim cov corrosion kuj ntawm cov khoom.

-

YY571F Friction Fastness Tester (Electric)

Siv rau kev ntsuam xyuas kev sib txhuam los ntsuas cov xim ceev hauv textile, knitwear, tawv, electrochemical hlau phaj, luam ntawv thiab lwm yam lag luam.

-

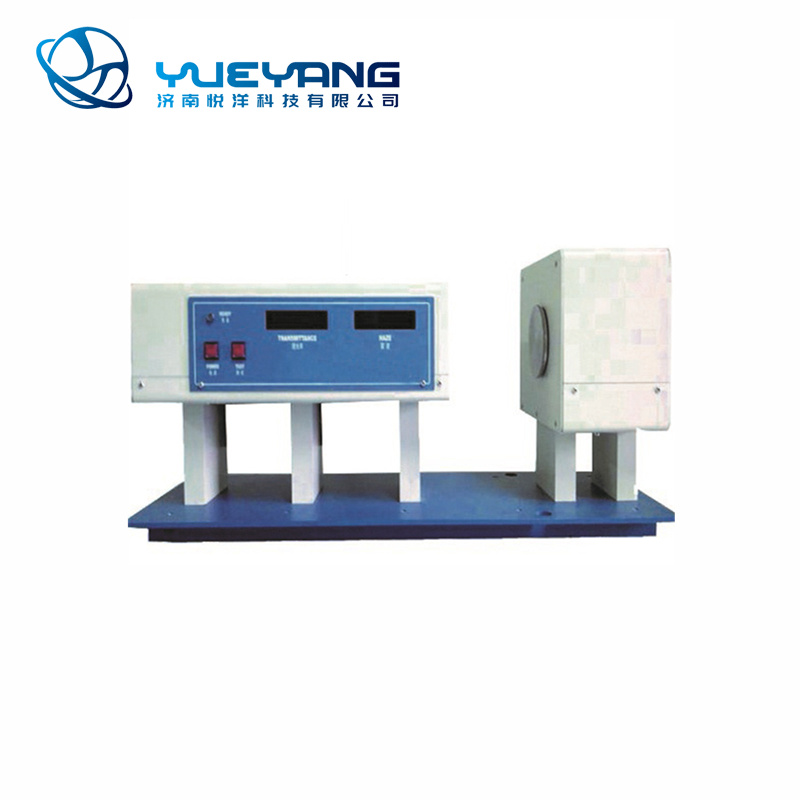

YYP122B Haze Meter

Txais cov teeb pom kev sib luag, kev sib cais hemispherical, thiab ib qho khoom siv pob photoelectric txais hom.

Lub microcomputer tsis siv neeg tswj kev ntsuas qhov system thiab cov ntaub ntawv ua haujlwm, kev ua haujlwm yooj yim,

tsis muaj pob qhov rooj, thiab tus qauv luam tawm tawm rub tawm, cia li tso saib tus nqi nruab nrab ntawm kev xa tawm

/ haze rov ntsuas. Cov txiaj ntsig kis tau mus txog 0.1﹪ thiab qhov kub hnyiab tau nce mus txog

0.01﹪.

-

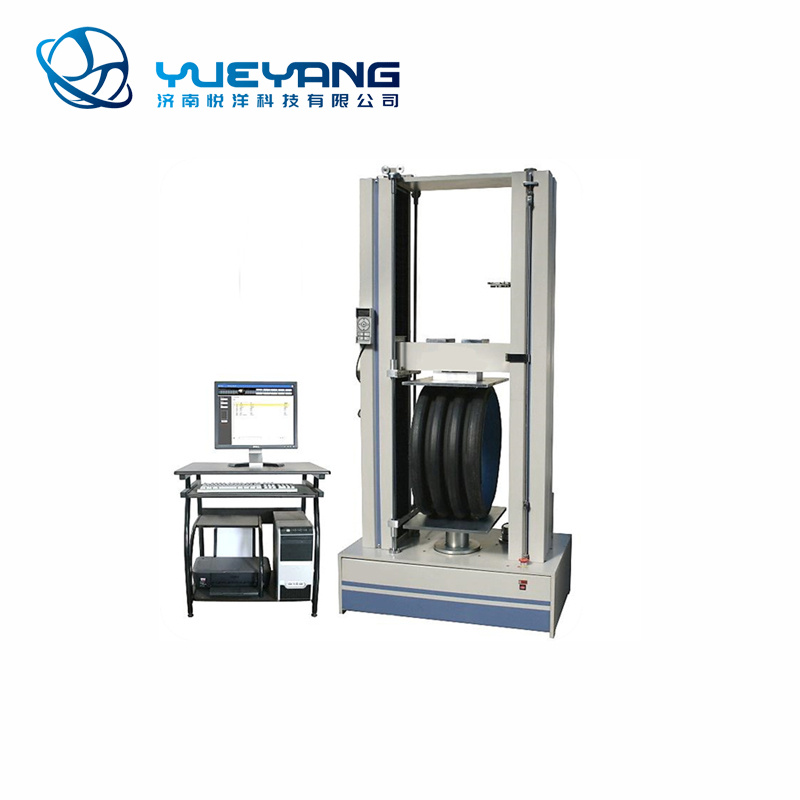

YYP-WDT-W-60B1 Electronic Universal Testing Tshuab

WDT series micro-tswj hluav taws xob universal kuaj tshuab rau ob chav ntsia hlau, tus tswv tsev, tswj, ntsuas, kev ua haujlwm sib koom ua ke.

-

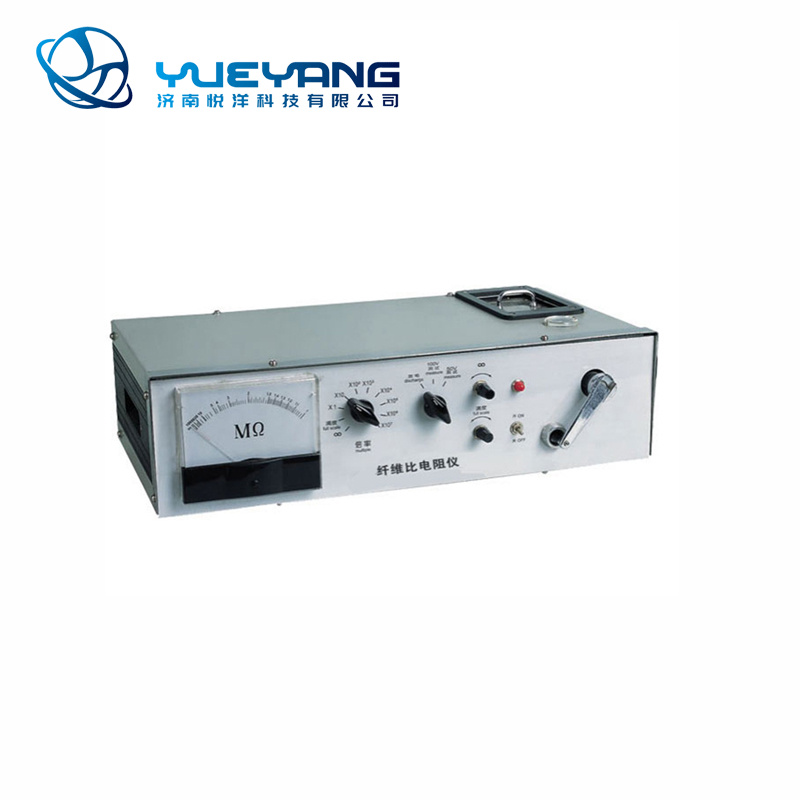

YY321 Fiber Ratio Resistance Meter

Siv los ntsuas qhov tshwj xeeb tsis kam ntawm ntau yam tshuaj fibers.

-

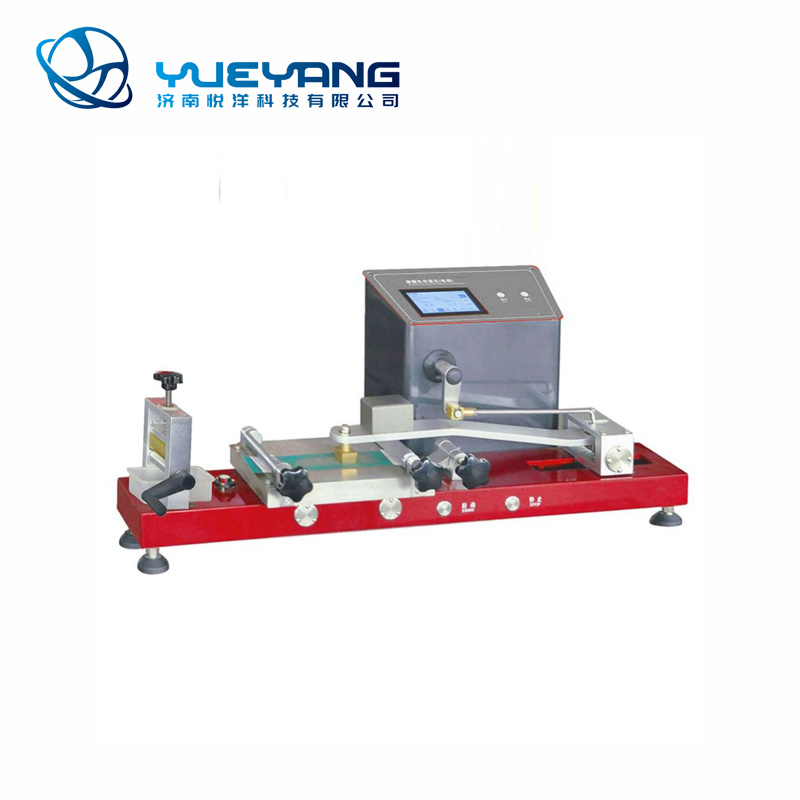

YY085B Npuag Shrinkage Printing kav

Siv rau cov ntawv luam tawm thaum lub sij hawm kuaj shrinkage.

-

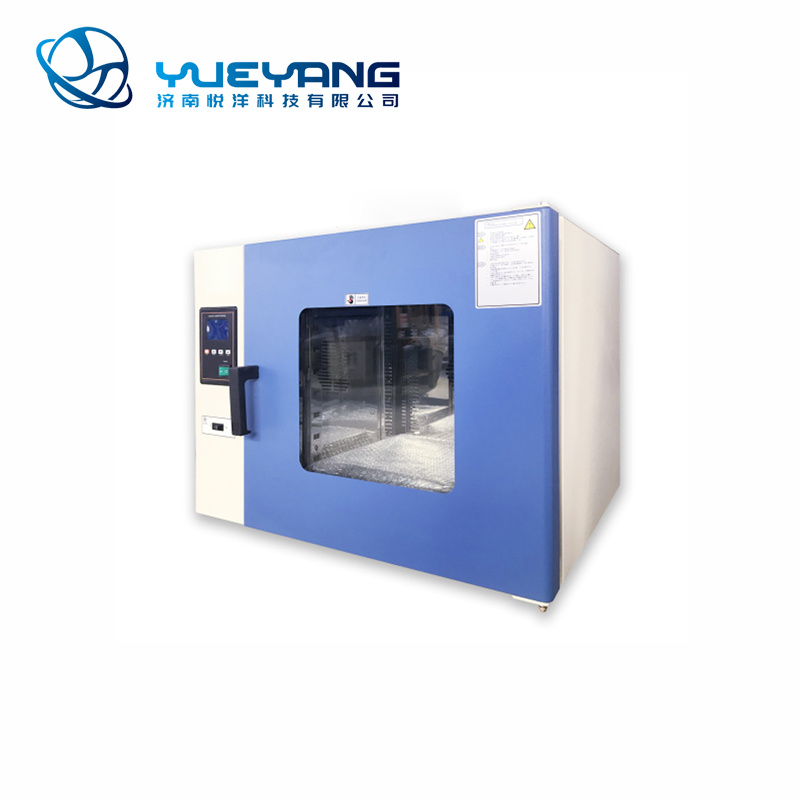

YYP252 Tshuab ziab khaub ncaws

1: Tus qauv loj-screen LCD zaub, tso saib ntau cov ntaub ntawv ntawm ib qho screen, cov ntawv qhia zaub mov-hom kev ua haujlwm interface, yooj yim to taub thiab ua haujlwm.

2: Cov kiv cua ceev tswj hom tau txais yuav, uas tuaj yeem hloov kho dawb raws li kev sim sib txawv.

3: Lub tshuab hluav taws xob tsim hluav taws xob tuaj yeem tso tawm cov dej vapor hauv lub thawv yam tsis muaj kev hloov kho.