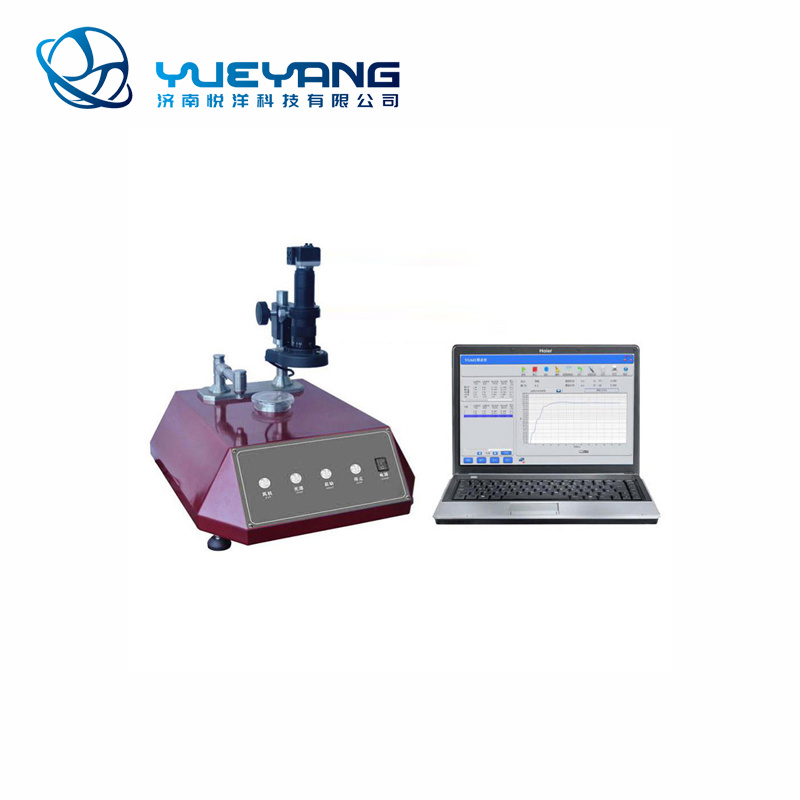

YY641 Cov Cuab Yeej Siv Rau Smelting Point

Siv rau hauv textile, tshuaj fiber, cov ntaub ntawv tsim kho, tshuaj, kev lag luam tshuaj lom neeg thiab lwm yam kev lag luam ntawm kev tshuaj xyuas cov organic, tuaj yeem pom tseeb cov khoom me me thiab cov khoom hauv qab lub xeev cua sov ntawm cov duab, kev hloov xim thiab peb lub xeev hloov pauv thiab lwm yam kev hloov pauv lub cev.

1. Kev siv lub koob yees duab CCD siab thiab cov kua siv lead ua kua, tuaj yeem pom tseeb cov txheej txheem yaj ntawm cov khoom;

2. PID algorithm siv los tswj cua sov kom ntseeg tau tias qhov kub nce siab ruaj khov;

3. Kev ntsuas tsis siv neeg, kev sib koom ua ke ntawm tib neeg thiab tshuab, tsis tas yuav tsum tau saib xyuas thaum lub sijhawm sim, yog li ua kom muaj kev tsim khoom, txhim kho kev ua haujlwm zoo;

4. Tus neeg siv-phooj ywg interface, cov ntaub ntawv ntsuas tuaj yeem rov qab taug qab (kub nce, melting point tus nqi, lub teeb nkhaus, duab xeem tuaj yeem khaws cia), kom ua tiav kev txo qis

5. Lub hom phiaj ntawm kev sib cav sib ceg hauv kev ua lag luam;

5. Kev tsim qauv zoo tshaj plaws, qhov chaw raug;

6. Muaj ob hom kev sim: microscopy thiab photometry, thiab photometry tuaj yeem suav cov txiaj ntsig tau.

7. Ntau yam kev siv (tshuaj, tshuaj lom neeg, cov ntaub ntawv tsim kho, textile, tshuaj fiber thiab lwm yam kev siv).

1. Qhov ntsuas qhov kub ntawm qhov yaj: chav tsev kub ~ 320 ° C

2. Tus nqi nyeem tsawg kawg nkaus: 0.1 ° C

3. Kev ntsuas rov ua dua: ± 1 ° C (ntawm <200 ° C), ± 2 ° C (ntawm 200 ° C-300 ° C)

4. Tus nqi cua sov tawm: 0.5, 1,2,3,5 (°C/min)

5. Lub tshuab tsom iav loj hlob: ≤100 zaug

6. Kev siv ib puag ncig: kub 0 ~ 40 ° C qhov kub thiab txias 45 ~ 85% RH

7. Qhov hnyav ntawm lub cuab yeej: 10kg