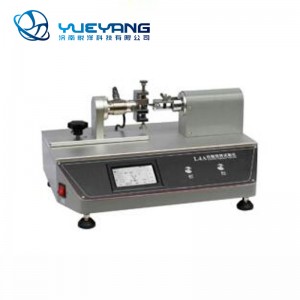

(Tuam Tshoj) YY026H-250 Lub Tshuab Hluav Taws Xob Tensile Zog Tester

Cov cuab yeej no yog kev sim ua haujlwm zoo hauv kev lag luam textile hauv tsev, muaj zog, ua haujlwm zoo, ua haujlwm tau zoo, ruaj khov thiab txhim khu kev qha. Siv dav hauv xov paj, ntaub, luam ntawv thiab zas xim, ntaub, khaub ncaws, zipper, tawv, tsis yog woven, geotextile thiab lwm yam lag luam ntawm kev tawg, rhuav, tev tawm, xaws, elasticity, thiab kev sim nkag.

GB/T3923.1, GB/T3917.2-2009, GB/T3917.3-2009, GB/T3917.4-2009, GB/T3917.5-2009, GB/T13773.1-2008, FZ/T80007.1-

1. Txais yuav servo tsav tsheb thiab lub cev muaj zog (vector tswj), lub sijhawm teb lub cev muaj zog luv luv, tsis muaj kev ceev overrush, ceev tsis sib xws.

2. Nruab nrog encoder rau kev tswj hwm qhov chaw ntsuas thiab kev ntev.

3. Nruab nrog lub sensor siab precision, "STMicroelectronics" ST series 32-bit MCU, 24 A/D converter.

4. Nruab nrog lub tshuab cua, lub clip tuaj yeem hloov tau, thiab tuaj yeem kho raws li cov neeg siv khoom cov ntaub ntawv.

5. Kev txhawb nqa software online Windows operating system,

6. Cov cuab yeej txhawb nqa tus tswv tsev thiab lub khoos phis tawj ob txoj kev tswj hwm.

7. Ua ntej qhov kev teeb tsa software digital.

8. Qhov ntev ntawm qhov chaw digital, qhov chaw tsis siv neeg.

9. Kev tiv thaiv ib txwm muaj: kev tiv thaiv hloov kho tshuab, kev mus ncig sab saud thiab qis dua, kev tiv thaiv overload, over-voltage, over-current, overheating, under-voltage, under-current, leakage automatic tiv thaiv, kev tiv thaiv thaum muaj xwm ceev hloov tes.

10. Cov neeg siv khoom tuaj yeem teeb tsa qhov kev xaiv siab tshaj plaws thiab kev txiav txim siab ntawm kev rhuav tshem, tev tawv.

11. Kev ntsuas tus nqi zog: kev ntsuas tus lej digital (tus lej tso cai), kev txheeb xyuas cov cuab yeej yooj yim, kev tswj hwm qhov tseeb.

12. Tag nrho lub tshuab hluav taws xob tus qauv tsim qauv, kev saib xyuas thiab txhim kho cov cuab yeej yooj yim.

1. Cov software txhawb nqa Windows operating system, tawm ntawm lub thawv, yooj yim heev, tsis tas yuav kawm ua haujlwm.

2. Lub khoos phis tawj online software txhawb nqa Suav thiab Askiv ua haujlwm.

3. Ua kom qhov kev sim uas tus neeg siv tau lees paub ruaj khov, txhua qhov parameter muaj tus nqi qub, tus neeg siv tuaj yeem hloov kho.

4. Qhov chaw teeb tsa parameter: tus lej khoom siv piv txwv, xim, pawg, tus lej qauv thiab lwm yam tsis tau teeb tsa thiab luam tawm lossis khaws cia rau hauv.

5. Lub luag haujlwm ntawm kev zooming rau hauv thiab tawm ntawm cov ntsiab lus xaiv ntawm qhov nkhaus xeem. Nyem rau ib qho taw tes ntawm qhov taw tes xeem kom pom cov nqi tensile thiab elongation.

6. Daim ntawv qhia txog cov ntaub ntawv xeem tuaj yeem hloov mus ua Excel, Word, thiab lwm yam, tsis siv neeg saib xyuas cov txiaj ntsig xeem, yooj yim rau kev sib txuas nrog cov neeg siv khoom lag luam software tswj hwm.

7. Cov kab ntsuas raug khaws cia rau hauv PC, yog li ntawd thiaj li sau tau cov lus nug.

8. Cov software kuaj suav nrog ntau txoj kev kuaj lub zog ntawm cov khoom siv, yog li qhov kev kuaj ntawd yooj yim dua, ceev dua, raug dua thiab pheej yig dua.

9. Qhov xaiv ntawm qhov nkhaus tuaj yeem zoom rau hauv thiab tawm ntawm qhov yuav tsum tau ua thaum lub sijhawm xeem.

10. Cov qauv kuaj tau muab tso tawm rau hauv daim ntawv qhia tib yam li cov txiaj ntsig ntawm kev xeem.

11. Kev ua haujlwm ntawm cov ntsiab lus suav lej, uas yog nyeem cov ntaub ntawv ntawm qhov nkhaus ntsuas, tuaj yeem muab tag nrho 20 pawg ntawm cov ntaub ntawv, thiab tau txais qhov elongation lossis lub zog sib xws raws li qhov sib txawv ntawm lub zog lossis elongation los ntawm cov neeg siv.

15. Muaj ntau yam nkhaus superposition muaj nuj nqi.

16. Cov chav ntsuas tuaj yeem hloov pauv tau raws li qhov xav tau, xws li Newton, phaus, kilogram zog thiab lwm yam.

17. Kev tshuaj xyuas software muaj nuj nqi: tawg taw tes, tawg taw tes, kev ntxhov siab taw tes, cov txiaj ntsig taw tes, thawj modulus, elastic deformation, yas deformation, thiab lwm yam.

18. Siv tshuab tswj ob txoj kev (tus tswv tsev, lub khoos phis tawj), yog li ntawd qhov kev xeem yooj yim thiab ceev, cov txiaj ntsig ntawm kev xeem yog nplua nuj thiab ntau yam (cov ntaub ntawv qhia, cov kab nkhaus, cov duab qhia, cov ntawv qhia).

1. Ntau yam thiab tus nqi indexing: 2500N, 0.1N;

2. Qhov kev daws teeb meem ntawm lub zog muaj nqis 1/60000

3. Qhov tseeb ntawm lub zog sensor: ≤ ± 0.05% F · S

4. Lub tshuab thauj khoom raug: tag nrho ntau yam ntawm 2% ~ 100% txhua qhov tseeb ntawm qhov tseeb ≤ ± 0.1%, qib: 1 theem

5. Qhov kev hloov kho qhov ceev ntawm lub beam (nce, nqis, kev tswj ceev, qhov ceev ruaj khov): (10 ~ 500) hli / feeb (nyob rau hauv qhov ntau ntawm qhov chaw dawb)

6. Kev mob stroke zoo: 800mm

7. Kev daws teeb meem hloov chaw: 0.01 hli

8. Qhov tsawg kawg nkaus clamping nrug: 10 hli

9. Clamping qhov chaw nrug hom: qhov chaw digital, qhov chaw tsis siv neeg

10. Gantry dav: 360mm

11. Kev hloov pauv chav tsev: N, CN, IB, IN

12. Cov ntaub ntawv khaws cia (tus tswv tsev): ≥2000 pawg

13. Lub hwj chim muab hluav taws xob: 220V, 50HZ, 1000W

14. Qhov loj sab nraud: 800mm × 600mm × 2000mm (L × W × H)

15. Qhov hnyav: 220kg

1. Tus Tswv Tsev --- 1 Teeb

2. Cov Clamps:

1). Siv tes rub tawm cov clamps

2). Kev tuav cov khoom siv clamps

3. Kev tshuaj xyuas software hauv online

4. Cov khoom siv sib txuas lus hauv online

5. Lub Xov Tooj Hauv Zos: 2500N

6. Kev Teeb tsa Software: Kev Tswj Xyuas Kev Ua Haujlwm Zoo (CD-ROM)

7. Cov clamps tensile:

2N--1 Daim

5N--1 Daim

10N --- 1 Daim

1) GB/T3923.1 --- Cov Ntaub - Kev txiav txim siab ntawm lub zog tensile thaum tawg thiab elongation thaum tawg - Txoj kev strip

2) GB/T3923.2 --- Cov ntaub - Kev txiav txim siab ntawm cov khoom tensile ntawm cov ntaub - Kev txiav txim siab ntawm kev tawg lub zog thiab elongation thaum tawg - Txoj kev tuav

3) GB/T3917.2-2009 --- Kev rhuav tshem cov khoom ntawm cov ntaub - Kev txiav txim siab ntawm lub zog rhuav tshem ntawm cov qauv ris tsho (ib qho seam)

4) GB/T3917.3-2009--Cov Ntaub - Kev txiav txim siab ntawm lub zog rhuav tshem ntawm cov qauv trapezoidal

5) GB/T3917.4-2009 --- Cov ntaub - Cov khoom rhuav ntawm cov qauv lus (ob chav sib txuas) - Kev txiav txim siab ntawm lub zog rhuav

6) GB/T3917.5-2009 --- Cov ntaub - Cov khoom rhuav ntawm cov ntaub - Kev txiav txim siab ntawm lub zog rhuav ntawm cov qauv airfoil (ib leeg sib txuas)

7) GB/T19976-2005 ---- Cov ntaub - Kev txiav txim siab ntawm lub zog tawg - Txoj kev pob

8) FZ/80007.1-2006 --- Txoj kev sim rau lub zog tev ntawm cov khaub ncaws siv cov nplaum sab hauv