Cov Cuab Yeej Ntsuas Textile

-

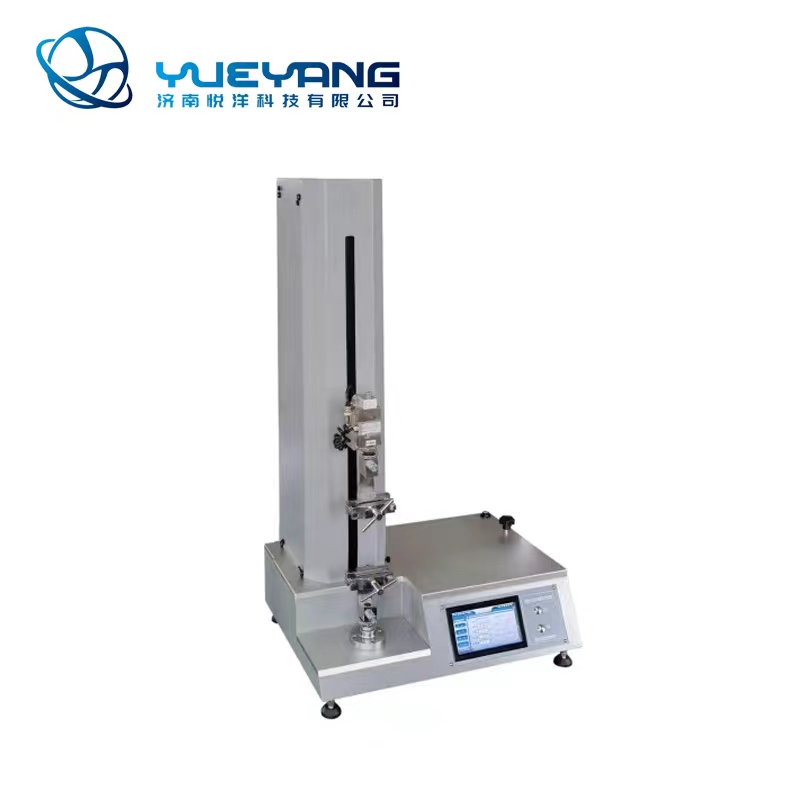

YY021G Hluav Taws Xob Spandex Xov Paj Lub Zog Tester

Siv rau kev sim lub zog tensile tawg thiab tawg elongation ntawm spandex, paj rwb, wool, silk, hemp, tshuaj fiber, hlua, nuv ntses, cladded xov thiab hlau hlau. Lub tshuab no siv ib lub tshuab microcomputer tswj system, automatic data processing, tuaj yeem tso saib thiab luam tawm Suav teb xeem daim ntawv qhia.

-

YY3000A Cov Cuab Yeej Siv Dej Txias Rau Kev Tiv Thaiv Huab Cua Laus (Kub Ib Txwm)

Siv rau kev sim laus dag ntawm ntau yam ntaub, xim, tawv, yas, xim, txheej, khoom siv sab hauv tsheb, geotextiles, khoom siv hluav taws xob thiab khoom siv hluav taws xob, cov khoom siv xim thiab lwm yam khoom siv simulated lub teeb hnub ci kuj tseem tuaj yeem ua tiav qhov kev sim xim ceev rau lub teeb thiab huab cua. Los ntawm kev teeb tsa cov xwm txheej ntawm lub teeb irradiance, kub, av noo thiab nag hauv chav kuaj, qhov chaw ib puag ncig simulated xav tau rau kev sim yog muab los sim cov kev hloov pauv ntawm cov khoom siv xws li xim ploj, laus, transmittance, tev tawv, tawv, mos thiab tawg.

-

YY605B Ironing Sublimation Xim Fastness Tester

Siv rau kev sim xim sublimation kom ruaj khov rau kev ironing ntawm ntau yam ntaub.

-

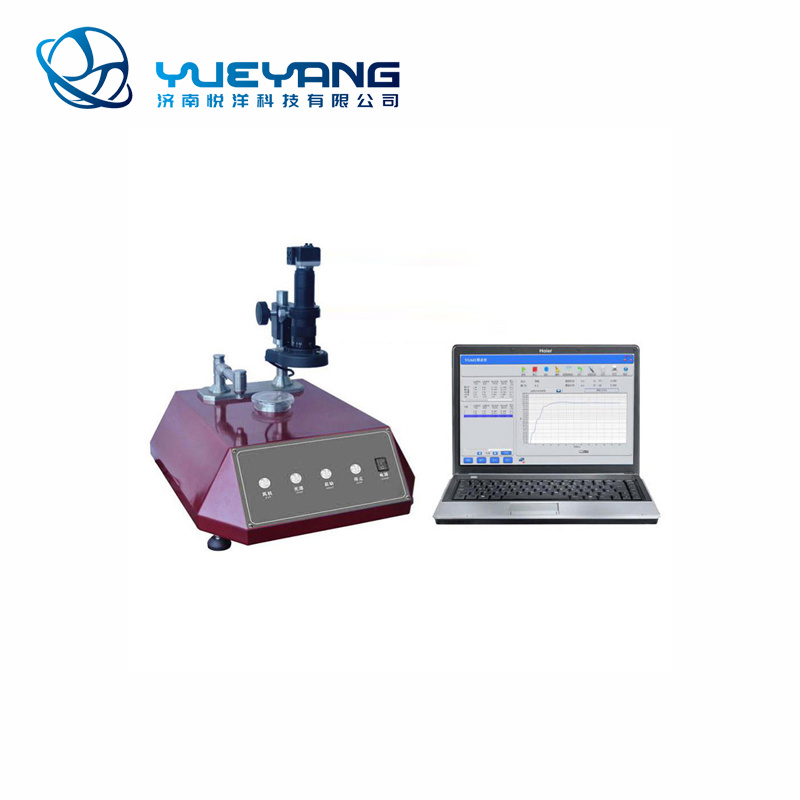

YY641 Cov Cuab Yeej Siv Rau Smelting Point

Siv rau hauv textile, tshuaj fiber, cov ntaub ntawv tsim kho, tshuaj, kev lag luam tshuaj lom neeg thiab lwm yam kev lag luam ntawm kev tshuaj xyuas cov organic, tuaj yeem pom tseeb cov khoom me me thiab cov khoom hauv qab lub xeev cua sov ntawm cov duab, kev hloov xim thiab peb lub xeev hloov pauv thiab lwm yam kev hloov pauv lub cev.

-

(Tuam Tshoj) YY607B Phaj Hom Nias Cuab Yeej

Siv rau kev ua cov qauv sib xyaw ua ke ntawm cov ntaub ntawv kub yaj rau khaub ncaws.

-

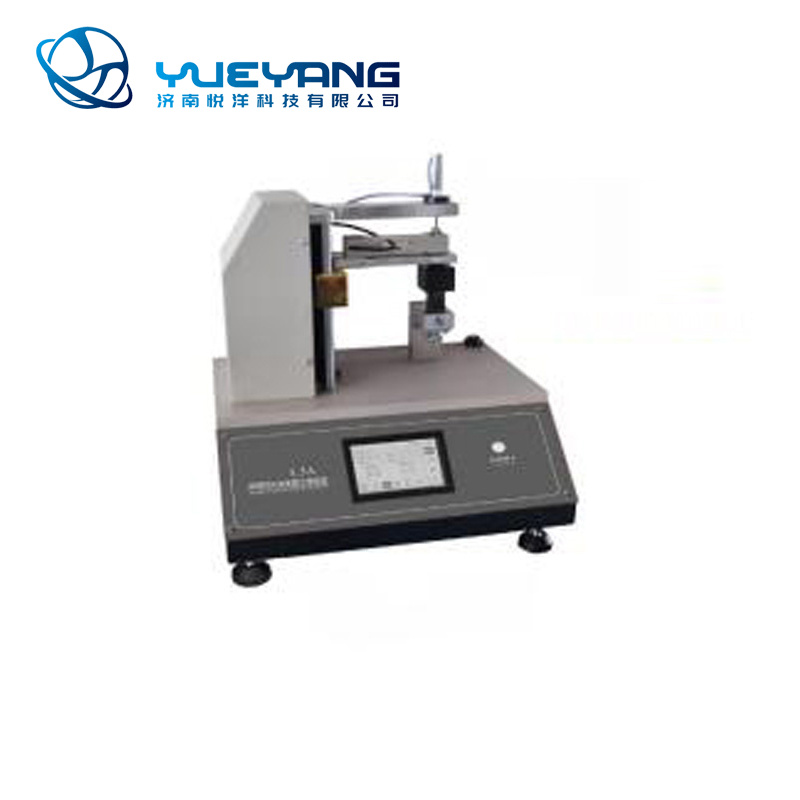

YY-L3A Zip Rub lub taub hau Tensile Lub Zog Tester

Siv rau kev sim lub zog tensile ntawm hlau, txhaj tshuaj molding, nylon zipper hlau rub lub taub hau nyob rau hauv qhov kev hloov pauv tshwj xeeb.

-

YY021Q Tsis Siv Neeg Ib Leeg Xov Paj Lub Zog Tester

Lub zog ntawm cov xov paj ib leeg tsis siv neegtus neeg simtswj los ntawm lub khoos phis tawj, siv rau kev txiav txim siab ntawm polyester (polyester), polyamide (nylon), polypropylene (polypropylene), cellulose fiber thiab lwm yam tshuaj fiber filament thiab deformation silk, paj rwb xov, cua spinning xov, nplhaib spinning xov thiab lwm yam paj rwb xov, BCF ntaub pua plag silk. Cov cim qhia lub cev xws li tawg lub zog, tawg elongation, tawg lub zog, tawg lub sijhawm, pib modulus thiab tawg ua haujlwm ntawm ib qho xov xws li xov xaws yog sib xws nrog Windows 7/10 32/64 lub khoos phis tawj operating system thiab nruab nrog lub vijtsam loj kov. Tom qab lub tshuab thiab computer software txuas nrog, cov kev teeb tsa tuaj yeem teeb tsa ntawm lub vijtsam kov. Kuj tseem tuaj yeem ua haujlwm ntawm computer software, kev nrhiav cov ntaub ntawv thiab ua cov zis tsis siv neeg.

-

(Tuam Tshoj)YY(B)331C-Lub tshuab ntswj xov paj digital (muaj lub tshuab luam ntawv)

Siv rau kev txiav txim siab ntawm kev sib ntswg, kev sib ntswg tsis sib xws thiab kev sib ntswg ntawm txhua hom paj rwb, ntaub plaub, txhob lo lo ntxhuav, cov xov paj tshuaj fiber, roving thiab xov paj.

-

YY–UTM-01A Tshuab Kuaj Khoom Siv Thoob Ntiaj Teb

Lub tshuab no yog siv rau cov hlau thiab cov hlau tsis yog hlau (xws li cov ntaub ntawv sib xyaw) tensile, compression, bending, shear, peeling, tearing, load, relaxation, reciprocating thiab lwm yam khoom ntawm kev tshuaj xyuas kev ua tau zoo li qub, tuaj yeem tau txais REH, Rel, RP0.2, FM, RT0.5, RT0.6, RT0.65, RT0.7, RM, E thiab lwm yam kev xeem. Thiab raws li GB, ISO, DIN, ASTM, JIS thiab lwm yam qauv hauv tsev thiab thoob ntiaj teb rau kev sim thiab muab cov ntaub ntawv.

-

YY605M Ironing Sublimation Xim Fastness Tester

Siv rau kev sim xim kom ruaj khov rau ironing thiab sublimation ntawm txhua yam ntaub muaj xim.

-

(Tuam Tshoj) YY751A Chav Kub thiab av noo tas mus li

Chav ntsuas kub thiab av noo tas li tseem hu ua chav ntsuas kub thiab av noo siab thiab qis, chav ntsuas kub siab thiab qis uas tau teeb tsa tau, tuaj yeem ua qauv ntau yam kub thiab av noo ib puag ncig, feem ntau yog rau cov khoom siv hluav taws xob, hluav taws xob, khoom siv hauv tsev, tsheb thiab lwm yam khoom thiab cov ntaub ntawv hauv qhov xwm txheej ntub thiab kub tas li, kub siab, kub qis thiab hloov pauv ntub thiab kub, sim cov ntsuas kev ua tau zoo thiab kev hloov pauv ntawm cov khoom. Nws kuj tseem siv tau rau txhua yam ntaub thiab ntaub kom kho qhov kub thiab av noo ua ntej sim.

-

YY981B Cov Tshuab Rho Tawm Sai Rau Cov Roj Fiber

Siv rau kev rho tawm sai ntawm ntau yam roj fiber thiab kev txiav txim siab ntawm cov roj qauv.

-

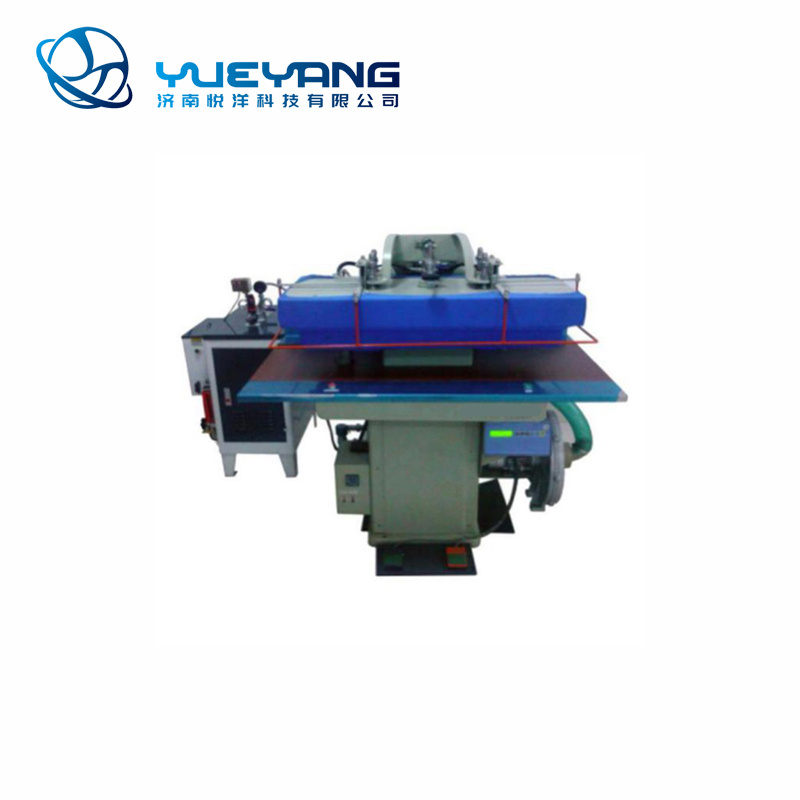

YY607Z Tsis Siv Neeg Chav Ironing Shrinkage Tester

1. PHom kev tswj: pneumatic

2. Air siab hloov kho ntau yam: 0– 1.00Mpa; + / – 0.005 MPa

3. IQhov loj ntawm lub pwm roning: L600 × W600mm

4. Shom kev txhaj tshuaj pab pawg: hom txhaj tshuaj pwm sab saud -

YY-L3B Zip Rub lub taub hau Tensile Lub Zog Tester

Siv rau kev sim lub zog tensile ntawm hlau, txhaj tshuaj molding, nylon zipper hlau rub lub taub hau nyob rau hauv qhov kev hloov pauv tshwj xeeb.

-

YY025A Hluav Taws Xob Wisp Xov Paj Zog Tester

Siv rau kev ntsuas lub zog thiab kev ntev ntawm ntau yam xov paj.

-

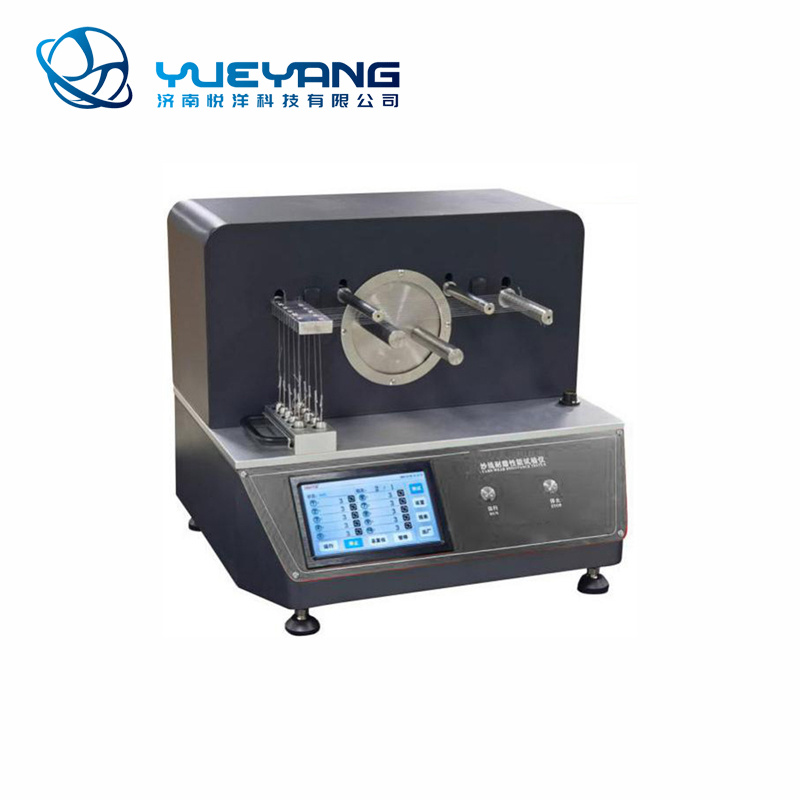

YY609A Xov Paj Hnav Tiv Thaiv Tester

Txoj kev no yog qhov tsim nyog rau kev txiav txim siab ntawm cov khoom siv tiv taus kev hnav ntawm cov xov paj rwb thiab cov tshuaj luv luv.

-

YY631M Kev Ntsuas Qhov Hws Sai

Siv rau kev sim xim ntawm ntau yam ntaub rau acid, alkaline hws, dej, dej hiav txwv, thiab lwm yam.

-

![[Tuam Tshoj] YY-L6LA Zipper daim kab xev folding qaug zog tester](https://cdn.globalso.com/jnyytech/图片120.png)

[Tuam Tshoj] YY-L6LA Zipper daim kab xev folding qaug zog tester

Yuav ua piv txwv siv daim kab xev zipper, rov ua dua qhov khoov ntawm qee qhov ceev thiab qee lub kaum sab xis, thiab sim qhov zoo ntawm daim kab xev zipper.

-

YY001-Khawm Tensile Lub Zog Tester (cov zaub pointer)

Nws yog siv los sim lub zog ntawm cov nyees khawm ntawm txhua hom ntaub. Kho cov qauv ntawm lub hauv paus, tuav lub nyees khawm nrog lub clamp, tsa lub clamp kom tshem lub nyees khawm, thiab nyeem qhov nqi nro uas xav tau los ntawm lub rooj nro. Yog los txhais lub luag haujlwm ntawm tus neeg tsim khaub ncaws kom ntseeg tau tias cov nyees khawm, cov nyees khawm thiab cov khoom siv tau ruaj ntseg rau ntawm cov khaub ncaws kom tiv thaiv cov nyees khawm kom tsis txhob tawm ntawm cov khaub ncaws thiab ua rau muaj kev pheej hmoo ntawm kev raug nqos los ntawm tus menyuam. Yog li ntawd, txhua lub nyees khawm, cov nyees khawm thiab cov khoom siv ntawm cov khaub ncaws yuav tsum tau kuaj los ntawm lub zog ntawm lub nyees khawm.

-

YY2301 Xov Paj Tensiometer

Nws feem ntau yog siv rau kev ntsuas qhov zoo li qub thiab dynamic ntawm cov xov paj thiab cov xov paj uas yooj ywm, thiab tuaj yeem siv rau kev ntsuas qhov nrawm ntawm ntau yam xov paj hauv cov txheej txheem ua tiav. Qee qhov piv txwv ntawm cov ntawv thov yog raws li nram no: Kev lag luam knitting: Kev kho kom raug ntawm qhov nrawm ntawm cov looms voj voog; Kev lag luam hlau: tshuab kos duab hlau thiab winding; Tib neeg ua fiber: Tshuab ntswj; Tshuab thauj khoom, thiab lwm yam; Paj rwb textile: tshuab winding; Kev lag luam fiber optical: tshuab winding.