Cov khoom

-

(Tuam Tshoj) YYP113-4 PAT Khoom Siv

Kev Taw Qhia Khoom:

PAT Fixture feem ntau yog siv rau kev sim lub zog sib txuas ntawm cov ntawv corrugated.

-

(Tuam Tshoj)YYP113-3 FCT Cov Tshuab Txiav Qauv

Kev Taw Qhia:

Lub tshuab txiav qauv FCT yog lub tshuab kuaj tshwj xeeb uas tsim nyog rau kev sim lub zog siab tiaj tus

(FCT) ntawm corrugated board 8, uas tuaj yeem txiav cov qauv ntawm cov khoom sai thiab raug

thaj chaw teev tseg. Nws yog ib qho khoom siv pabcuam zoo tagnrho rau corrugated board thiab carton

cov chaw tsim khoom, kev tshawb fawb txog kev tshawb fawb thiab kev saib xyuas zoo thiab kev tshuaj xyuas cov chaw haujlwm.

-

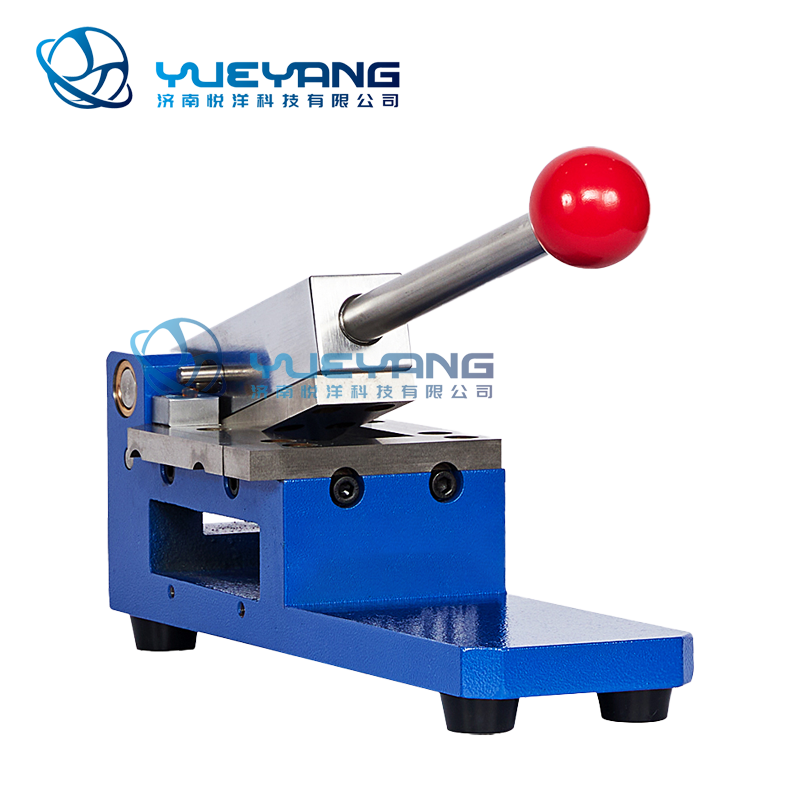

(Tuam Tshoj) YYP113-2 ECT Cov Tshuab Txiav Qauv

I.KhoomKuvkev taw qhia:

Lub tshuab ntsuas qhov siab ntawm ntug (adhesion) feem ntau yog siv rau ntug

kev sim siab thiab kev kuaj kev nplaum, ceev thiab raug txiav qhov

qhov loj me ntawm cov qauv, yog daim ntawv corrugated thiab thawv ntawv

kev tsim khoom, kev tshawb fawb txog kev tshawb fawb thiab kev saib xyuas zoo thiab kev tshuaj xyuas

cov chaw haujlwm ntawm cov khoom siv sim zoo tagnrho.

-

(Tuam Tshoj) YYP113-1 RCT Cov Tshuab Txiav Qauv

Kev Taw Qhia Khoom:

Lub tshuab ntsuas lub nplhaib yog qhov tsim nyog rau kev txiav cov qauv uas xav tau rau lub zog siab ntawm lub nplhaib ntawv.

Nws yog ib qho sampler tshwj xeeb tsim nyog rau kev sim lub zog ntawm lub nplhaib ntawv (RCT), thiab yog ib qho kev pab xeem zoo tagnrho

rau kev ua ntawv, ntim khoom, kev tshawb fawb txog kev tshawb fawb, kev tshuaj xyuas zoo thiab lwm yam lag luam thiab

cov chav haujlwm.

-

(Tuam Tshoj) YYP113 Crush Tester

Khoom muaj nuj nqi:

1. Txheeb xyuas lub zog nias ntawm lub nplhaib (RCT) ntawm cov ntawv corrugated puag

2. Kev ntsuas ntawm cov ntawv corrugated ntug compression zog (ECT)

3. Kev txiav txim siab ntawm lub zog compressive ntawm corrugated board (FCT)

4. Txheeb xyuas lub zog sib txuas ntawm cov ntawv corrugated (PAT)

5. Txheeb xyuas lub zog nias tiaj tiaj (CMT) ntawm daim ntawv corrugated puag

6. Txheeb xyuas lub zog nias ntug (CCT) ntawm daim ntawv corrugated puag

-

(Tuam Tshoj) YYP10000-1 Crease & stiffness Tester Sample Cutter

Lub tshuab txiav qauv crease & stiffness yog qhov tsim nyog rau kev txiav cov qauv uas xav tau rau kev sim crease & stiffness xws li ntawv, cardboard thiab daim ntawv nyias.

-

(Tuam Tshoj) YYP 10000 Lub Tshuab Ntsuas Qhov Ntswg Thiab Qhov Nyuaj

Tus Qauv

GB/T 23144,

GB/T 22364,

ISO 5628,

ISO 2493

-

(Tuam Tshoj) YYCS820P Lub Rooj Ntev Spectrophotometer

Kev Taw Qhia

Qhov no yog lub tshuab ntsuas xim ntse, yooj yim siv thiab muaj qhov tseeb siab. Nws siv 7 nti kov npo, puv wavelength, Android operating system. Lub teeb pom kev zoo: kev cuam tshuam D/8° thiab kev xa tawm D/0° (UV suav nrog / UV tsis suav nrog), qhov tseeb siab rau kev ntsuas xim, lub cim xeeb loj, PC software, vim yog cov txiaj ntsig saum toj no, nws yog siv hauv chav kuaj rau kev tshuaj xyuas xim thiab kev sib txuas lus.

Cov txiaj ntsig ntawm cov cuab yeej

1). Txais yuav qhov kev cuam tshuam D/8° thiab kev xa tawm D/0° geometry los ntsuas ob qho tib si opaque thiab pob tshab.

2). Kev Tshawb Fawb Txog Kev Tshawb Fawb Txog Kev Siv Ob Txoj Kev Kho Qhov Muag

Cov thev naus laus zis no tuaj yeem nkag mus rau ob qho tib si kev ntsuas thiab cov ntaub ntawv siv rau ib puag ncig sab hauv ntawm cov cuab yeej kom ntseeg tau tias cov cuab yeej raug thiab ruaj khov mus sij hawm ntev.

-

(Tuam Tshoj) YY501B Cov Pa Dej Kis Tus Nqi Tester

I.Kev siv cov cuab yeej:

Siv rau kev ntsuas qhov dej noo permeability ntawm cov khaub ncaws tiv thaiv kev kho mob, ntau yam ntaub coated, composite ntaub, composite zaj duab xis thiab lwm yam ntaub ntawv.

II. Kev Sib Tham Txheem:

1.GB 19082-2009 – Cov khaub ncaws tiv thaiv kev kho mob pov tseg uas yuav tsum tau ua 5.4.2 cov dej noo permeability;

2.GB/T 12704-1991 —Txoj kev txiav txim siab txog cov dej noo ntawm cov ntaub - Txoj kev khob dej noo 6.1 Txoj kev A txoj kev nqus dej noo;

3.GB/T 12704.1-2009 – Cov ntaub ntawv siv rau kev ntsuas dej noo – Ntu 1: txoj kev nqus dej noo;

4.GB/T 12704.2-2009 – Cov ntaub ntawv siv rau kev ntsuas dej noo – Ntu 2: txoj kev ua kom qhuav;

5.ISO2528-2017—Cov ntaub ntawv ntawv-Kev txiav txim siab ntawm tus nqi kis dej vapor (WVTR)–Gravimetric (phaj) txoj kev

6.ASTM E96; JIS L1099-2012 thiab lwm yam qauv.

-

(Tuam Tshoj) YY-90 Tshuaj Ntsuam Xyuas Ntshav - Kov-screen

IUsaib:

Lub tshuab ntsuas ntsev tsuag feem ntau yog siv rau kev kho qhov chaw ntawm ntau yam khoom siv, suav nrog xim. Electroplating. Inorganic thiab coated, anodized. Tom qab cov roj tiv thaiv xeb thiab lwm yam kev kho mob tiv thaiv xeb, qhov kev tiv thaiv corrosion ntawm nws cov khoom raug kuaj.

II.Nta:

1. Cov khoom siv digital zaub tswj hwm tag nrho cov qauv hluav taws xob digital, kev tswj qhov kub thiab txias kom raug, lub neej ua haujlwm ntev, ua tiav cov haujlwm sim;

2. Thaum ua haujlwm, lub interface zaub yog dynamic zaub, thiab muaj lub tswb ceeb toom kom ceeb toom txog qhov xwm txheej ua haujlwm; Cov cuab yeej siv ergonomic technology, yooj yim rau kev khiav lag luam, yooj yim dua rau cov neeg siv;

3. Nrog rau lub kaw lus ntxiv dej tsis siv neeg / phau ntawv, thaum qib dej tsis txaus, nws tuaj yeem rov ua kom tiav qib dej, thiab qhov kev sim tsis raug cuam tshuam;

4. Lub tshuab tswj kub siv lub vijtsam kov LCD, PID tswj yuam kev ± 01.C;

5. Kev tiv thaiv kub dhau ob npaug, ceeb toom txog qib dej tsis txaus kom ntseeg tau tias siv tau zoo.

6. Lub chaw kuaj mob siv txoj kev ua kom sov ncaj qha, qhov kub thiab txias yog ceev thiab sib xws, thiab lub sijhawm tos txais tau txo qis.

7. Lub qhov iav precision nozzle yog sib npaug zos diffused los ntawm lub conical disperser ntawm lub pej thuam tsuag nrog adjustable pos huab thiab pos huab ntim, thiab ntuj poob rau ntawm daim npav xeem, thiab xyuas kom meej tias tsis muaj crystallization ntsev blockage.

-

(Tuam Tshoj) YYP643 Chav Kuaj Xyuas Kev Kub Ntxhov Ntshav

YYP643 Chav kuaj xeb ntsev nrog kev tswj hwm PID tshiab tshaj plaws yog dav siv.

siv rau hauv

kev sim tshuaj tsuag ntsev ntawm cov khoom siv electroplated, xim, tshuaj pleev xim, tsheb

thiab cov khoom siv maus taus, cov khoom siv dav hlau thiab tub rog, cov txheej tiv thaiv ntawm cov hlau

cov ntaub ntawv,

thiab cov khoom lag luam xws li cov tshuab hluav taws xob thiab hluav taws xob.

-

(Tuam Tshoj) YYP-400BT Melt Flow Indexer

Melt flow Indexer (MFI) yog hais txog qhov zoo lossis qhov ntim ntawm cov yaj los ntawm tus qauv pwm txhua 10 feeb ntawm qee qhov kub thiab qhov hnyav, qhia los ntawm MFR (MI) lossis MVR tus nqi, uas tuaj yeem paub qhov txawv ntawm cov yam ntxwv ntws viscous ntawm thermoplastics hauv lub xeev molten. Nws yog qhov tsim nyog rau cov yas engineering xws li polycarbonate, nylon, fluoroplastic thiab polyarylsulfone nrog qhov kub siab melting, thiab tseem rau cov yas nrog qhov kub qis melting xws li polyethylene, polystyrene, polyacrylic, ABS resin thiab polyformaldehyde resin. Siv dav hauv cov khoom siv yas raw, kev tsim yas, cov khoom yas, petrochemical thiab lwm yam lag luam thiab cov tsev kawm qib siab thiab tsev kawm qib siab, cov chav tshawb fawb, cov chaw tshuaj xyuas khoom.

-

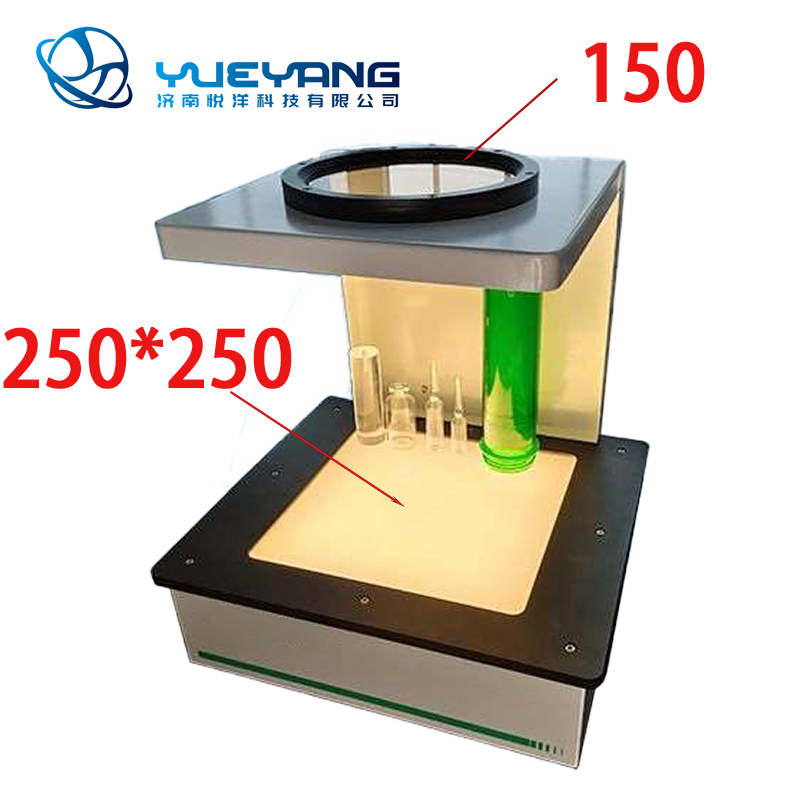

(Tuam Tshoj)YYPL03 Polariscope Strain Viewer

YYPL03 yog ib qho cuab yeej sim uas tsim los raws li tus qauv "GB/T 4545-2007 Txoj kev sim rau kev ntxhov siab sab hauv hauv cov fwj iav", uas yog siv los sim kev ua haujlwm annealing ntawm cov fwj iav thiab cov khoom iav thiab tshuaj xyuas kev ntxhov siab sab hauv ntawm

cov khoom.

-

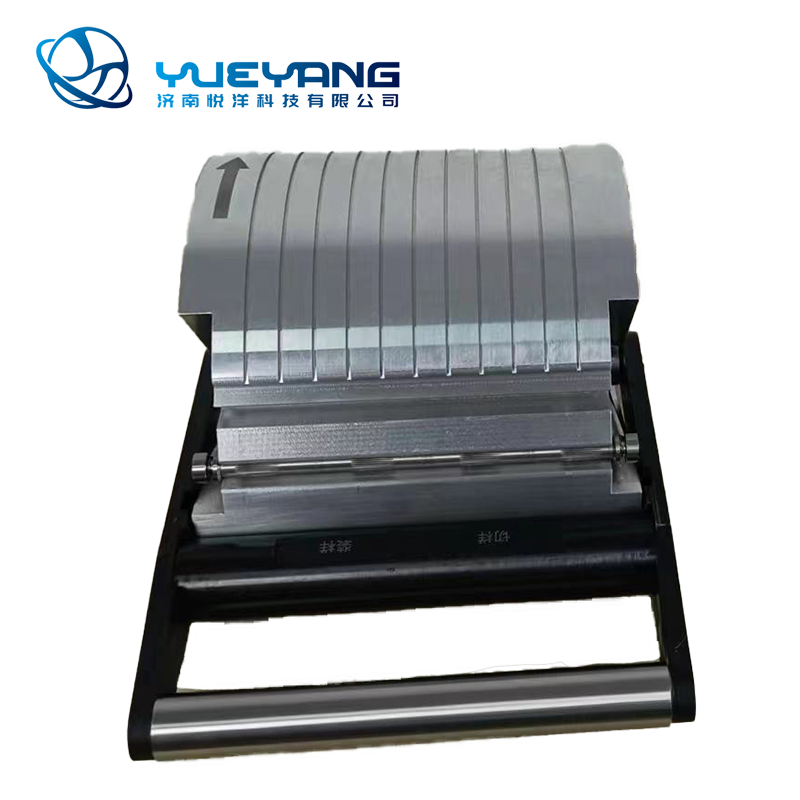

(Tuam Tshoj) YYP 114E Stripe Sampler

Lub tshuab no yog tsim rau kev txiav cov qauv ncaj nraim ntawm cov yeeb yaj kiab bidirectional stretched, unidirectional stretched film thiab nws cov yeeb yaj kiab composite, nyob rau hauv kab nrog

GB/T1040.3-2006 thiab ISO527-3:1995 tus qauv yuav tsum tau ua. Lub ntsiab feature

yog tias qhov kev ua haujlwm yooj yim thiab yooj yim, ntug ntawm qhov txiav spline yog huv si,

thiab cov khoom siv kho tshuab qub ntawm zaj duab xis tuaj yeem khaws cia tau.

-

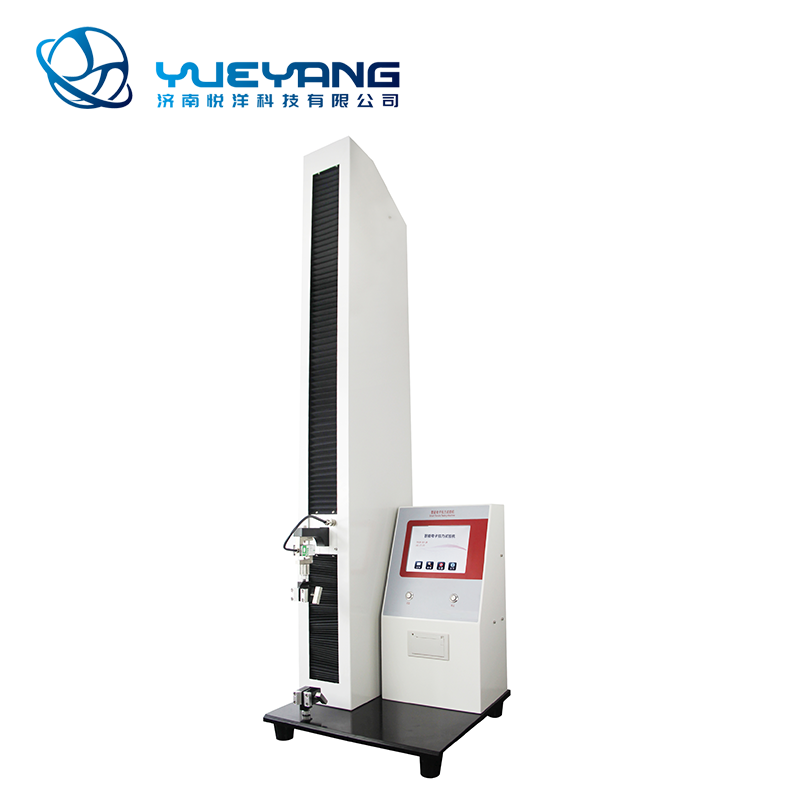

(Tuam Tshoj) YYL100 Peel Lub Zog Tensile Tester

Lub tshuab kuaj lub zog tev tawm yog ib hom cuab yeej tshiab tsim los ntawm peb lub tuam txhab

lub tuam txhab raws li cov qauv hauv tebchaws tshiab. Nws yog siv rau hauv

cov ntaub ntawv sib xyaw, daim ntawv tso tawm thiab lwm yam lag luam thiab lwm yam kev tsim khoom

thiab cov chaw tshuaj xyuas khoom muag uas xav tau txiav txim siab lub zog ntawm tev tawv.

-

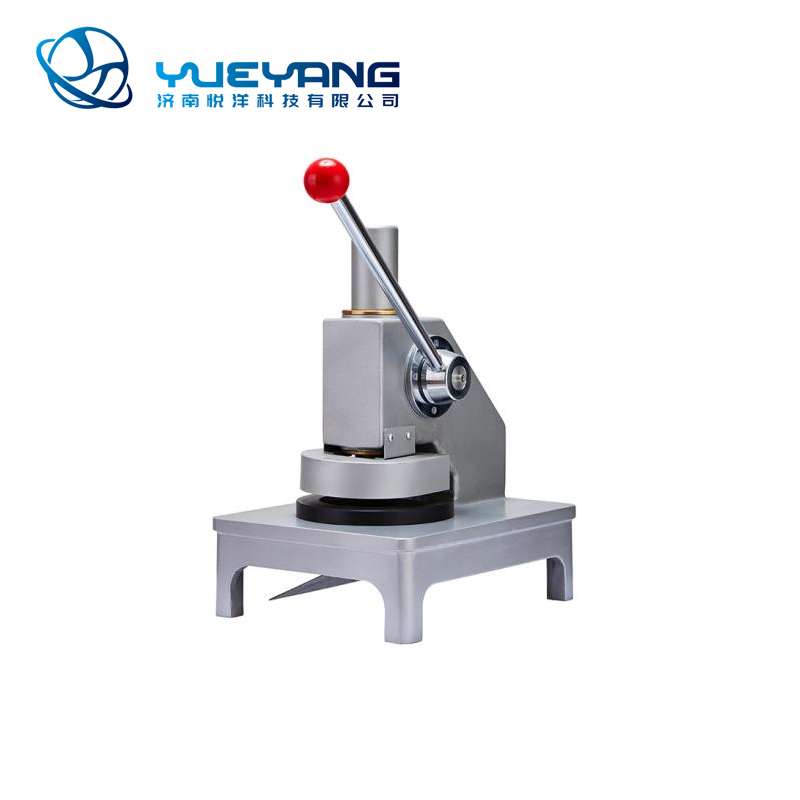

(Tuam Tshoj) YT-DL100 Lub Tshuab Txiav Qauv Voj Voog

Lub voj voog sampler yog ib qho sampler tshwj xeeb rau kev txiav txim siab ntau ntawm

cov qauv qauv ntawm daim ntawv thiab cov ntawv paperboard, uas tuaj yeem ua tau sai thiab

txiav cov qauv ntawm thaj chaw tus qauv kom raug, thiab yog qhov kev sim pabcuam zoo tagnrho

cov cuab yeej siv rau kev ua ntawv, ntim khoom thiab kev saib xyuas zoo

thiab kev tshuaj xyuas kev lag luam thiab cov chaw haujlwm.

-

(Tuam Tshoj) YY-CMF Concora Nruab Nrab Fluter

Concora medium fulter yog cov khoom siv sim yooj yim rau kev ua kom tiaj tus corrugating

nias (CMT) thiab nias ntug corrugated (CCT) tom qab corrugating hauv

lub chaw kuaj mob. Nws yuav tsum tau siv ua ke nrog lub nplhaib tshwj xeeb nias

tshuab kuaj sampler thiab compression

-

(Tuam Tshoj) YYP-L12A Lub Tshuab Ua Pulper Siab

YYP-L12A lub tshuab sib tsoo pulp muaj zog heev, nws yog lub tshuab ua ntawv pulping uas siv rau hauv chav kuaj pulping uas siv cov kua tuab heev los yog cov kua tuab rov ua dua tshiab. Lub chaw kuaj siv los ua cov ntawv pulp, ua rau daim ntawv puas tsuaj, thiab qhov kev teeb tsa tseem ceeb ntawm daim ntawv pov tseg, yog kev ntsuas cov txheej txheem rov ua dua tshiab, cov tshuaj ntxiv thiab cov cuab yeej zoo, kawm txog kev pabcuam kuaj ntawv. Lub tshuab no muaj cov yam ntxwv ntawm kev hloov kho ceev ntawm phau ntawv, qhov kev qhia digital qhia txog kev sib hloov ceev thiab lub zog loj.

-

(Tuam Tshoj)YYP-L4A Lab Valley Beater

Lub tshuab no siv dav ua tus qauv sim raws li JIS thiab TAPPI. Tsis zoo li lub tshuab ntaus ib txwm muaj, lub yob yog kho, thiab lub nra hnyav tas li raug siv rau ntawm lub taub hau, yog li ntawd nws ib txwm muab lub zog ntaus sib npaug. Nws zoo heev tshwj xeeb tshaj yog thaum ntaus dawb thiab ntaus ntub. Yog li nws zoo heev rau kev tswj xyuas zoo.

-

(Tuam Tshoj) YYP101 Tshuab Ntsuas Kev Sib Tw Thoob Ntiaj Teb

Cov yam ntxwv kev txawj:

1. Kev mus ncig ua si ntev heev 1000 hli

2. Panasonic Hom Servo Tsav Tsheb Kev Ntsuas System

3. Lub tshuab ntsuas lub zog ntawm American CELTRON.

4. Kev sib tw kuaj cua