Cov Cuab Yeej Ntsuas Ntim Khoom Siv Ntawv & Yas

-

YY-CS300 Lub Ntsuas Qhov Ci

Cov ntawv thov:

Cov ntsuas gloss feem ntau yog siv rau hauv kev ntsuas qhov ci ntsa iab ntawm cov xim pleev xim, yas, hlau, ceramics, cov ntaub ntawv tsim kho thiab lwm yam. Peb lub ntsuas gloss ua raws li DIN 67530, ISO 2813, ASTM D 523, JIS Z8741, BS 3900 Part D5, JJG696 cov qauv thiab lwm yam.

Qhov Zoo ntawm Khoom

1). Kev Ntsuas Siab

Peb lub 'meter' gloss siv lub sensor los ntawm Nyiv Pooj, thiab lub processor chip los ntawm Tebchaws Meskas kom paub tseeb tias cov ntaub ntawv ntsuas tau raug.

Peb cov ntsuas gloss ua raws li JJG 696 tus qauv rau thawj chav kawm gloss meters. Txhua lub tshuab muaj daim ntawv pov thawj metrology los ntawm State Key Laboratory ntawm cov ntsuas niaj hnub thiab cov cuab yeej kuaj thiab Engineering center ntawm Ministry of Education hauv Suav teb.

2). Kev Ruaj Ntseg Zoo Tshaj Plaws

Txhua lub 'meter' gloss uas peb ua tau ua qhov kev sim hauv qab no:

412 qhov kev ntsuam xyuas calibration;

43200 kev ntsuam xyuas kev ruaj khov;

110 teev ntawm kev sim laus sai;

17000 kev sim kev co

3). Kev xis nyob tuav

Lub plhaub yog ua los ntawm Dow Corning TiSLV cov khoom, uas yog cov khoom siv uas zoo rau kev ywj pheej. Nws tiv taus UV thiab cov kab mob thiab tsis ua rau muaj kev ua xua. Qhov kev tsim no yog rau kev paub zoo dua rau tus neeg siv.

4). Muaj peev xwm roj teeb loj

Peb siv tag nrho txhua qhov chaw ntawm lub cuab yeej thiab tshwj xeeb ua cov roj teeb lithium siab ceev hauv 3000mAH, uas ua kom muaj kev sim tas mus li rau 54300 zaug.

5). Ntau Cov Duab Khoom

-

YYP122-110 Lub Tshuab Ntsuas Huab Cua

Cov txiaj ntsig ntawm cov cuab yeej

1). Nws ua raws li ASTM thiab ISO cov qauv thoob ntiaj teb ASTM D 1003, ISO 13468, ISO 14782, JIS K 7361 thiab JIS K 7136.

2). Cov cuab yeej siv no muaj daim ntawv pov thawj calibration los ntawm lub chaw kuaj mob thib peb.

3). Tsis tas yuav tsum tau ua kom sov so, tom qab ntsuas lub cuab yeej lawm, nws siv tau. Thiab lub sijhawm ntsuas tsuas yog 1.5 vib nas this xwb.

4). Peb hom teeb pom kev zoo A, C thiab D65 rau kev ntsuas qhov kaj thiab qhov ntsuas tag nrho.

5). 21 hli qhov kev xeem qhov.

6). Qhib thaj chaw ntsuas, tsis muaj kev txwv rau qhov loj ntawm cov qauv.

7). Nws tuaj yeem paub txog kev ntsuas kab rov tav thiab ntsug los ntsuas ntau hom ntaub ntawv xws li daim ntawv, zaj duab xis, kua, thiab lwm yam.

8). Nws siv lub teeb LED uas nws lub neej muaj peev xwm ncav cuag 10 xyoo.

-

YYP122-09 Lub Tshuab Ntsuas Huab Cua

Cov txiaj ntsig ntawm cov cuab yeej

1). Nws ua raws li cov qauv thoob ntiaj teb GB/T 2410, ASTM D1003/D1044 thiab nrog daim ntawv pov thawj calibration los ntawm lub chaw kuaj mob thib peb.

2). Tsis tas yuav tsum tau ua kom sov so, tom qab ntsuas lub cuab yeej lawm, nws siv tau. Thiab lub sijhawm ntsuas tsuas yog 1.5 vib nas this xwb.

3). Ob hom teeb pom kev zoo A, C rau kev ntsuas qhov kaj thiab qhov ntsuas tag nrho.

4). 21 hli qhov kev xeem qhov.

5). Qhib thaj chaw ntsuas, tsis muaj kev txwv rau qhov loj ntawm cov qauv.

6). Nws tuaj yeem paub txog kev ntsuas kab rov tav thiab ntsug los ntsuas ntau hom ntaub ntawv xws li daim ntawv, zaj duab xis, kua, thiab lwm yam.

7). Nws siv lub teeb LED uas nws lub neej muaj peev xwm ncav cuag 10 xyoo.

Lub ntsuas pa tawsDaim Ntawv Thov:

-

(Tuam Tshoj) YYP103B Lub Teeb Ci & Xim Meter

Brightness Xim Meter yog dav siv rau hauv papermaking, ntaub, luam ntawv, yas, ceramic thiab

porcelain enamel, cov khoom siv hauv kev tsim kho, cov nplej, kev ua ntsev thiab lwm yam kev kuaj xyuas uas

yuav tsum tau sim qhov dawb qhov daj, xim thiab chromatism.

-

-

(Tuam Tshoj) YY-DS200 Series Colorimeter

Cov yam ntxwv ntawm cov khoom

(1) Tshaj 30 Cov Ntsuas Ntsuas

(2) Soj ntsuam seb cov xim puas dhia teeb, thiab muab ze li ntawm 40 qhov chaw soj ntsuam lub teeb

(3) Muaj hom kev ntsuas SCI

(4) Muaj UV rau kev ntsuas xim fluorescent

-

-

-

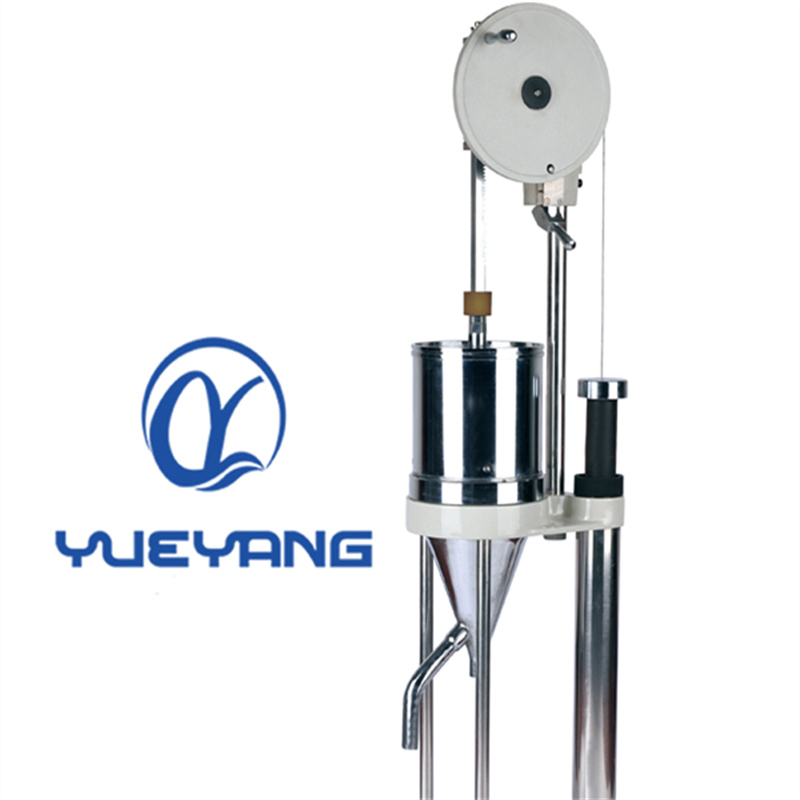

YYP116 Beating Freeness Tester (Tuam Tshoj)

Kev Taw Qhia Txog Khoom:

YYP116 Beating Pulp Tester siv los ntsuas lub peev xwm lim dej ntawm cov kua pulp uas raug ncua. Qhov ntawd yog hais txog kev txiav txim siab ntawm qib kev ntaus.

Cov yam ntxwv ntawm cov khoom :

Raws li qhov sib piv ntawm qhov sib txawv ntawm qhov ntaus degree thiab qhov ceev ntawm cov kua pulp uas raug ncua, tsim los ua Schopper-Riegler ntaus degree tester. YYP116 Beating Pulp

Lub tshuab ntsuas no siv los ntsuas qhov muaj peev xwm ntawm cov kua pulp suspending thiab

tshawb nrhiav cov mob fiber thiab ntsuas qhov degree ntawm kev ntaus.

Daim ntawv thov khoom:

Siv rau hauv kev sim lub peev xwm lim dej ntawm kev ncua kua pulp, uas yog hais txog kev txiav txim siab ntawm qib ntaus.

Cov qauv kev txawj ntse:

ISO 5267.1

GB/T 3332

QB/T 1054

-

YY8503 Crush Tester - Hom kov-screen (Tuam Tshoj)

Kev Taw Qhia Khoom:

YY8503 Kov npo crush tester tseem hu ua computer ntsuas thiab tswj compression tester, cardboard compression tester, hluav taws xob compression tester, ntug siab meter, lub nplhaib siab meter, yog lub cuab yeej yooj yim rau cardboard/ntawv compressive zog xeem (uas yog, ntawv ntim khoom xeem ntsuas), nruab nrog ntau yam khoom siv fixture tuaj yeem sim lub nplhaib compression zog ntawm lub hauv paus ntawv, tiaj compression zog ntawm cardboard, ntug siab zog, bonding zog thiab lwm yam kev xeem. Yuav kom cov ntawv tsim cov tuam txhab kom tswj cov nqi tsim khoom thiab txhim kho cov khoom zoo. Nws cov kev ua tau zoo thiab cov cim qhia kev ua tau raws li cov qauv hauv tebchaws.

Ua tau raws li tus qauv:

1.GB/T 2679.8-1995 — "Kev txiav txim siab ntawm lub zog nias ntawm daim ntawv thiab ntawv sau";

2.GB/T 6546-1998 "—-Kev txiav txim siab ntawm lub zog siab ntawm ntug ntawm Corrugated cardboard";

3.GB/T 6548-1998 "—-Kev txiav txim siab ntawm lub zog sib txuas ntawm cov ntawv corrugated";

4.GB/T 2679.6-1996 "—Kev txiav txim siab ntawm lub zog compression tiaj tus ntawm daim ntawv corrugated puag";

5.GB/T 22874 "- Kev txiav txim siab ntawm lub zog compression tiaj tus ntawm ib sab thiab ib sab corrugated cardboard"

Cov kev ntsuam xyuas hauv qab no tuaj yeem ua tiav nrog cov khoom siv sib xws:

1. Nruab nrog lub phaj ntsuas qhov siab ntawm lub nplhaib thiab lub tshuab ntsuas qhov siab tshwj xeeb los ua qhov kev ntsuas lub zog ntawm lub nplhaib (RCT) ntawm cov ntawv cardboard;

2. Nruab nrog ntug nias (kev sib txuas) cov qauv sampler thiab cov ntawv qhia pabcuam los nqa cov ntawv corrugated ntug nias lub zog xeem (ECT);

3. Nruab nrog lub zog kuaj lub zog tev tawv, kev xeem lub zog ntawm daim ntawv corrugated (peeling) (PAT);

4. Nruab nrog lub tshuab ntsuas siab tiaj tus los ua qhov kev sim siab tiaj tus (FCT) ntawm cov ntawv corrugated;

5. Lub zog compressive ntawm daim ntawv kuaj hauv paus (CCT) thiab lub zog compressive (CMT) tom qab corrugating.

-

YY- SCT500 Lub Tshuab Ntsuas Kev Sib Tw Luv (Tuam Tshoj)

- Kev Txheeb Xyuas:

Lub tshuab ntsuas kev sib zog luv luv yog siv rau kev tsim cov ntawv thiab cov ntawv rau cov thawv ntawv thiab cov thawv ntawv, thiab kuj tseem tsim nyog rau cov ntawv uas tau npaj los ntawm chav kuaj thaum lub sijhawm kuaj pulp.

II.Cov yam ntxwv ntawm cov khoom:

1. Ob chav lub tog raj kheej, pneumatic clamping qauv, txhim khu kev qha lav cov qauv txheem.

2.24-ntsis precision analog-rau-digital converter, ARM processor, ceev thiab raug sampling

3. 5000 pawg ntawm cov ntaub ntawv tuaj yeem khaws cia rau kev nkag mus tau yooj yim rau cov ntaub ntawv ntsuas keeb kwm.

4. Stepper motor tsav, qhov tseeb thiab ruaj khov, thiab rov qab sai, txhim kho kev sim ua haujlwm.

5. Kev ntsuam xyuas ntsug thiab kab rov tav tuaj yeem ua tiav hauv tib pawg, thiab ntsug thiab

cov nqi nruab nrab kab rov tav tuaj yeem luam tawm.

6. Kev txuag cov ntaub ntawv ntawm kev ua haujlwm tsis muaj zog tam sim ntawd, khaws cov ntaub ntawv ua ntej lub zog tsis ua haujlwm tom qab fais fab-rau

thiab tuaj yeem txuas ntxiv kev sim.

7. Cov kab nkhaus ntawm lub zog hloov chaw tiag tiag tau tshwm sim thaum lub sijhawm sim, uas yooj yim rau

cov neeg siv los saib xyuas cov txheej txheem sim.

III. Kev Sib Tham Tus Qauv:

ISO 9895, GB/T 2679 · 10

-

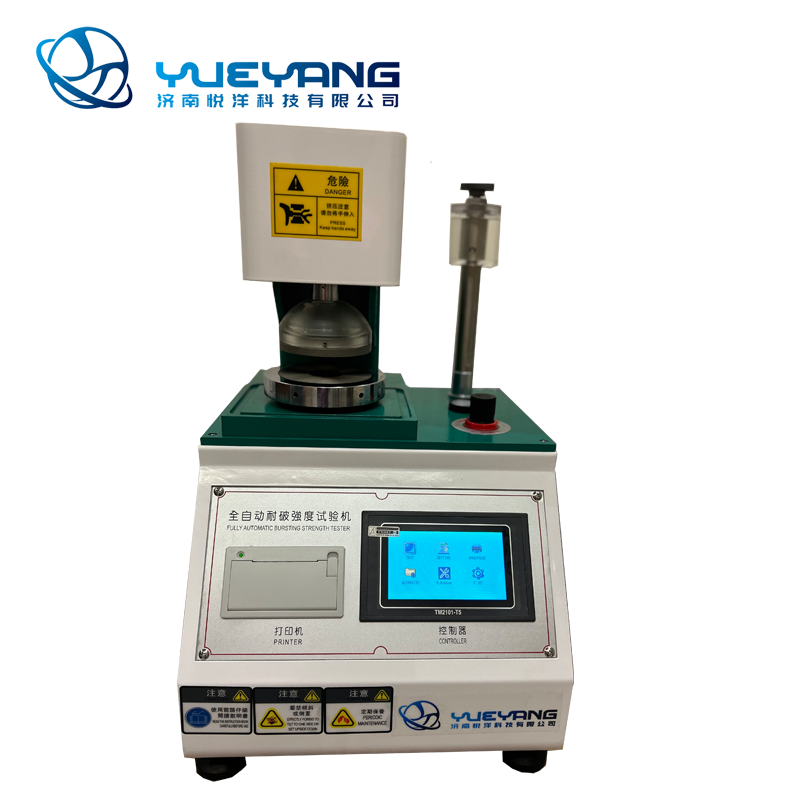

(Tuam Tshoj) YY109 Tsis Siv Neeg Bursting Lub Zog Tester (touchscreen interface)

Tus Qauv Sib Tham:

ISO 2759 Cardboard- -Kev Txheeb Xyuas Kev Tiv Thaiv Kev Tawg

GB / T 1539 Kev Txiav Txim Siab ntawm Board board Resistance

QB / T 1057 Kev Txheeb Xyuas Kev Tiv Thaiv Kev Tawg Ntawm Daim Ntawv Thiab Rooj Tsav Xwm

GB / T 6545 Kev Txiav Txim Siab ntawm Corrugated Break Resistance Strength

GB / T 454 Kev Txiav Txim Siab ntawm Kev Tiv Thaiv Kev Tawg Ntawv

ISO 2758 Daim Ntawv - -Kev Txheeb Xyuas Kev Tiv Thaiv Kev Tawg

-

-

(Tuam Tshoj) YYP-5024 Tshuab Kuaj Kev co

Daim ntawv thov teb:

Lub tshuab no yog tsim rau cov khoom ua si, khoom siv hluav taws xob, rooj tog, khoom plig, ceramics, ntim khoom thiab lwm yam

cov khoomrau kev sim tsheb thauj mus los simulated, raws li Tebchaws Meskas thiab Tebchaws Europe.

Ua tau raws li tus qauv:

EN ANSI, UL, ASTM, ISTA Cov qauv kev thauj mus los thoob ntiaj teb

Cov txheej txheem kev siv thiab cov yam ntxwv ntawm cov khoom siv:

1. Cov cuab yeej digital qhia txog kev co zaus

2. Synchronous ntsiag to siv txoj siv sia, suab nrov heev

3. Lub clamp qauv txais yuav hom kev taw qhia, yooj yim rau kev khiav lag luam thiab muaj kev nyab xeeb

4. Lub hauv paus ntawm lub tshuab txais yuav cov hlau hnyav nrog cov roj hmab tiv thaiv kev co,

uas yooj yim rau nruab thiab du khiav yam tsis tau txhim kho cov ntsia hlau anchor

5. Kev tswj ceev ntawm Dc motor, kev ua haujlwm du, muaj peev xwm thauj khoom tau zoo

6. Kev co ntawm lub zog (feem ntau hu ua hom nees), raws li European thiab Asmeskas

cov qauv kev thauj mus los

7. Hom kev co: tig (khiav nees)

8. Kev co zaus: 100 ~ 300rpm

9. Qhov siab tshaj plaws thauj khoom: 100kg

10. Qhov dav: 25.4 hli (1 ")

11. Qhov chaw ua haujlwm zoo: 1200x1000mm

12. Lub zog tsav tsheb: 1HP (0.75kw)

13. Qhov loj tag nrho: 1200 × 1000 × 650 (hli)

14. Lub Sijhawm: 0 ~ 99H99m

15. Tshuab hnyav: 100kg

16. Zaub zaus raug: 1rpm

17. Lub hwj chim muab hluav taws xob: AC220V 10A

-

(Tuam Tshoj) YYP124A Ob Chav Tis Pob Khoom Siv Ntsuas Kev Poob

Cov ntawv thov:

Lub tshuab kuaj poob ob sab caj npab feem ntau yog siv los ntsuas qhov cuam tshuam ntawm qhov poob poob rau ntawm cov ntim khoom hauv kev thauj mus los thiab kev thauj khoom thiab kev tshem tawm, thiab los ntsuas qhov

lub zog cuam tshuam ntawm lub ntim khoom thaum lub sijhawm tuav thiab qhov laj thawj ntawm lub ntim khoom

tsim.

Ntsib tustus qauv

Lub tshuab kuaj ob sab caj npab ua raws li cov qauv hauv tebchaws xws li GB4757.5-84

JISZ0202-87 ISO2248-1972(E)

-

YYP124B Zero Drop Tester (Tuam Tshoj)

Cov ntawv thov:

Lub tshuab ntsuas xoom poob feem ntau yog siv los ntsuas qhov cuam tshuam ntawm qhov poob poob rau ntawm cov ntim khoom hauv kev thauj mus los thiab kev thauj khoom thiab kev tshem tawm cov khoom, thiab los ntsuas qhov cuam tshuam ntawm cov ntim khoom hauv cov txheej txheem tuav thiab qhov laj thawj ntawm kev tsim cov ntim khoom. Lub tshuab ntsuas xoom poob feem ntau yog siv rau kev ntsuas poob ntim loj dua. Lub tshuab siv lub diav rawg zoo li "E" uas tuaj yeem txav mus rau hauv qab sai li tus neeg nqa khoom, thiab cov khoom kuaj tau sib npaug raws li qhov yuav tsum tau ua ntawm kev xeem (qhov chaw, ntug, lub kaum sab xis). Thaum lub sijhawm xeem, lub caj npab bracket txav mus rau hauv qab ntawm qhov ceev ceev, thiab cov khoom kuaj poob rau ntawm lub phaj hauv paus nrog lub diav rawg "E", thiab tau muab tso rau hauv lub phaj hauv qab hauv qab kev ua haujlwm ntawm lub tshuab nqus dej ua haujlwm siab. Hauv kev xav, lub tshuab ntsuas xoom poob tuaj yeem poob los ntawm qhov siab xoom, qhov siab poob yog teeb tsa los ntawm LCD maub los, thiab kev xeem poob yog ua tiav raws li qhov siab teeb tsa.

Txoj cai tswj:Tus qauv tsim ntawm lub cev poob dawb, ntug, Lub kaum sab xis thiab nto yog ua tiav los ntawm kev siv microcomputer xa tawm hluav taws xob tsim qauv.

Ua tau raws li tus qauv:

GB/T1019-2008

-

YYP124C Ib Caj Npab Drop Tester (Tuam Tshoj)

Cov Cuab Yeejsiv:

Ib txhais caj npab ntsuas kev poob Lub tshuab no yog siv tshwj xeeb los ntsuas kev puas tsuaj ntawm cov khoom ntim los ntawm kev poob, thiab los ntsuas lub zog cuam tshuam thaum lub sijhawm thauj mus los thiab kev tuav.

Ua tau raws li tus qauv:

ISO2248 JISZ0202-87 GB/T4857.5-92

Cov Cuab Yeejnta:

Lub tshuab kuaj ib sab caj npab tuaj yeem kuaj dawb rau ntawm qhov chaw, Lub kaum sab xis thiab ntug ntawm

pob khoom, nruab nrog cov cuab yeej ntsuas qhov siab digital thiab kev siv decoder rau kev taug qab qhov siab,

yog li ntawd qhov siab ntawm cov khoom poob tuaj yeem muab tau raws li qhov tseeb, thiab qhov yuam kev qhov siab ua ntej poob tsis pub ntau tshaj 2% lossis 10MM. Lub tshuab siv ib txhais caj npab ob chav kem, nrog rau kev pib dua hluav taws xob, kev tswj hwm hluav taws xob poob thiab lub cuab yeej nqa hluav taws xob, yooj yim siv; Lub cuab yeej buffer tshwj xeeb heev

txhim kho lub neej ua haujlwm, kev ruaj khov thiab kev nyab xeeb ntawm lub tshuab. Ib sab caj npab teeb tsa rau qhov yooj yim tso

ntawm cov khoom.

-

(Tuam Tshoj) YY-WT0200 – Lub tshuab hluav taws xob sib npaug

[Scope ntawm daim ntawv thov]:

Nws yog siv rau kev sim qhov hnyav gram, suav cov xov paj, feem pua, cov lej me me ntawm cov ntaub, tshuaj lom neeg, ntawv thiab lwm yam lag luam.

[Cov qauv cuam tshuam]:

GB/T4743 "kev txiav txim siab ntawm cov xov paj linear density Hank method"

ISO 2060.2 Cov Ntaub - Kev Txiav Txim Siab ntawm cov xov paj linear density - Txoj Kev Skein

ASTM, JB5374, GB/T4669/4802.1, ISO23801, thiab lwm yam

[Cov yam ntxwv ntawm cov cuab yeej]:

1. Siv cov cuab yeej ntsuas siab thiab cov cuab yeej tswj hwm microcomputer ib leeg;

2. Nrog kev tshem tawm tare, kev ntsuas tus kheej, nco, suav, kev ua txhaum thiab lwm yam haujlwm;

3. Nruab nrog lub hau cua tshwj xeeb thiab qhov hnyav calibration;

[Cov kev tsis sib xws]:

1. Qhov hnyav tshaj plaws: 200g

2. Tus nqi kawm ntawv tsawg kawg nkaus: 10mg

3. Tus nqi pov thawj: 100mg

4. Qib raug: III

5. Lub hwj chim muab hluav taws xob: AC220V ± 10% 50Hz 3W

-

(Tuam Tshoj) YYP-R2 Roj Da Dej Kub Shrink Tester

Kev Taw Qhia Txog Kev Siv Cuab Yeej:

Lub tshuab ntsuas cua sov yog qhov tsim nyog rau kev sim qhov kev ua haujlwm ntawm cov khoom siv cua sov, uas tuaj yeem siv rau cov yas zaj duab xis substrate (PVC zaj duab xis, POF zaj duab xis, PE zaj duab xis, PET zaj duab xis, OPS zaj duab xis thiab lwm yam cua sov ntsws zaj duab xis), cov khoom ntim khoom sib xyaw ua ke, PVC polyvinyl chloride daim ntawv tawv, lub hnub ci cell backplane thiab lwm yam khoom siv nrog cua sov ntsws kev ua tau zoo.

Cov yam ntxwv ntawm cov cuab yeej:

1. Kev tswj hwm microcomputer, PVC zaub mov hom kev ua haujlwm interface

2. Tsim qauv tib neeg, ua haujlwm yooj yim thiab ceev ceev

3. Kev siv tshuab ua haujlwm siab, kev sim raug thiab txhim khu kev qha

4. Cov cua sov nruab nrab uas tsis hloov pauv, qhov cua sov dav dav

5. Kev siv tshuab tswj kub digital PID tsis yog tsuas yog tuaj yeem ncav cuag qhov kub thiab txias sai xwb, tab sis kuj tseem tiv thaiv kev hloov pauv kub

6. Lub sijhawm ua haujlwm tsis siv neeg kom paub tseeb tias qhov tseeb ntawm kev xeem

7. Nruab nrog cov qauv qauv tuav zaj duab xis grid kom ntseeg tau tias cov qauv ruaj khov yam tsis muaj kev cuam tshuam los ntawm qhov kub thiab txias

8. Kev tsim qauv compact, lub teeb thiab yooj yim nqa

-

(Tuam Tshoj) YY174 Cua Da Dej Kub Shrinkage Tester

Kev siv cov cuab yeej:

Nws tuaj yeem ntsuas qhov thermal shrinkage force, txias shrinkage force, thiab thermal shrinkage rate ntawm cov yas zaj duab xis thaum lub sijhawm thermal shrinkage. Nws yog qhov tsim nyog rau kev txiav txim siab qhov thermal shrinkage force thiab thermal shrinkage rate siab tshaj 0.01N.

Ua tau raws li tus qauv:

GB/T34848,

IS0-14616-1997,

DIN53369-1976